Nanoscale defects could boost energy storage materials

By David Nutt

Some imperfections pay big dividends.

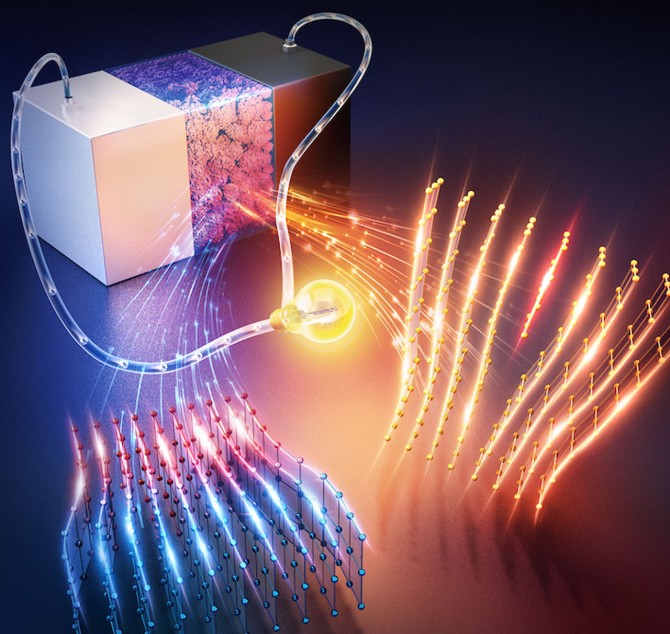

A Cornell-led collaboration used X-ray nanoimaging to gain an unprecedented view into solid-state electrolytes, revealing previously undetected crystal defects and dislocations that may now be leveraged to create superior energy storage materials.

The group’s paper, “X-ray Nanoimaging of Crystal Defects in Single Grains of Solid-State Electrolyte Li7-3xAlxLa3Zr2O12,” published April 29 in Nano Letters, a publication of the American Chemical Society. The paper’s lead author is doctoral student Yifei Sun.

For a half-century, materials scientists have been investigating the effects of tiny defects in metals. The evolution of imaging tools has now created opportunities for exploring similar phenomena in other materials, most notably those used for energy storage.

A group led by Andrej Singer, assistant professor and David Croll Sesquicentennial Faculty Fellow in the Department of Materials Science and Engineering, uses synchrotron radiation to uncover atomic-scale defects in battery materials that conventional approaches, such as electron microscopy, have failed to find.

The Singer Group is particularly interested in solid-state electrolytes because they could potentially be used to replace the liquid and polymer electrolytes in lithium-ion batteries. One of the major drawbacks of liquid electrolytes is they are susceptible to the formation of spiky dendrites between the anode and cathode, which short out the battery or, even worse, cause it to explode.

Solid-state electrolytes have the virtue of not being flammable, but they present challenges of their own. They don’t conduct lithium ions as strongly or quickly as fluids, and maintaining contact between the anode and cathode can be difficult. Solid-state electrolytes also need to be extremely thin; otherwise, the battery would be too bulky and any gain in capacity would be negated.

The one thing that could make solid-state electrolytes viable? Tiny defects, Singer said.

“These defects might facilitate ionic diffusion, so they might allow the ions to go faster. That’s something that’s known to happen in metals,” he said. “Also like in metals, having defects is better in terms of preventing fracture. So they might make the material less prone to breaking.”

Singer’s group collaborated with Nikolaos Bouklas, assistant professor in the Sibley School of Mechanical and Aerospace Engineering and a co-author of the paper, who helped them understand how defects and dislocations might impact the mechanical properties of solid-state electrolytes.

The Cornell team then partnered with researchers at Virginia Tech – led by Feng Lin, the paper’s co-senior author – who synthesized the sample: a garnet crystal structure, lithium lanthanum zirconium oxide (LLZO), with various concentrations of aluminum added in a process called doping.

Using the Advanced Photon Source at the U.S. Department of Energy’s Argonne National Laboratory, they employed a technique called Bragg Coherent Diffractive Imaging in which a pure, columnated X-ray beam is focused – much like a laser pointer – on a single micron-sized grain of LLZO. Electrolytes consist of millions of these grains. The beam created a 3D image that ultimately revealed the material’s morphology and atomic displacements.

“These electrolytes were assumed to be perfect crystals,” Sun said. “But what we find are defects such as dislocations and grain boundaries that haven’t been reported before. Without our 3D imaging, which is extremely sensitive to defects, it would be likely impossible to see those dislocations because the dislocation density is so low.”

The researchers now plan to conduct a study that measures how the defects impact the performance of solid-state electrolytes in an actual battery.

“Now that we know exactly what we’re looking for, we want to find these defects and look at them as we operate the battery,” Singer said. “We are still far away from it, but we may be at the beginning of a new development where we can design these defects on purpose to make better energy storage materials.”

Co-authors include postdoctoral fellow Oleg Gorobstov and doctoral students Daniel Weinstock and Ryan Bouck, from the Singer lab; and researchers at Virginia Tech and Argonne National Laboratory.

The research was supported by the National Science Foundation.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe