Bacteria-coated nanofiber electrodes digest pollutants

By Blaine Friedlander

Cornell materials scientists and bioelectrochemical engineers may have created an innovative, cost-competitive electrode material for cleaning pollutants in wastewater.

The researchers created electro-spun carbon nanofiber electrodes and coated them with a conductive polymer, called PEDOT, to compete with carbon cloth electrodes available on the market. When the PEDOT coating is applied, an electrically active layer of bacteria – Geobacter sulfurreducens – naturally grows to create electricity and transfer electrons to the novel electrode.

The conducting nanofibers create a favorable surface for this bacteria, which digests pollutants from the wastewater and produces electricity, according to the research.

“Electrodes are expensive to make now, and this material could bring the price of electrodes way down, making it easier to clean up polluted water,” said co-lead author Juan Guzman, a doctoral candidate in the field of biological and environmental engineering.

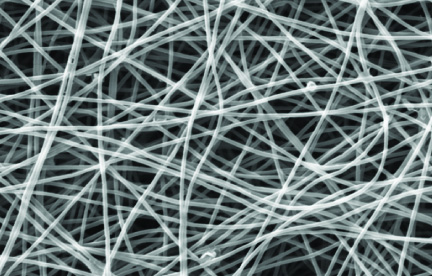

Under a microscope, the carbon nanofiber electrode resembles a kitchen scrubber. The electrode was made by co-lead author Meryem Pehlivaner, M.S. ’13, currently a doctoral student at Northeastern University, with senior author Margaret Frey, professor of fiber science and an associate dean of the College of Human Ecology. Pehlivaner fabricated the carbon nanofibers via electrospinning and carbonization processes. After a few hours electrospinning, a thick nanofiber sheet – visible to the naked eye – emerges.

Pehlivaner reached out to Guzman and senior author Lars Angenent, professor of biological and environmental engineering, for collaboration in applying the carbon nanofiber electrodes to simultaneous wastewater treatment and production of electrical energy.

The customizable carbon nanofiber electrode was used for its high porosity, surface area and biocompatibility with the bacteria. By adhering PEDOT, the material gets an improved function, according to the researchers.

Guzman said wastewater treatment plants do not employ this method – yet. On a large scale, the bacteria at the electrode could capture and degrade pollutants from the wastewater that flows by it. Such a technology can improve wastewater treatment by allowing systems to take up less land and increase throughput.

Concepts like this happen on campuses where faculty and students want to communicate and collaborate, Angenent said. “This defines radical collaboration,” he said. “We have fiber scientists talking to environmental engineers, from two very different Cornell colleges, to create reality from an idea – that was more or less a hunch – that will make cleaning wastewater better and a little more inexpensive.”

The research, “Performance of Electro-Spun Carbon Nanofiber Electrodes With Conductive Poly (3,4-Ethylenedioxythiophene) Coatings in Bioelectrochemical Systems,” will be published July 15 in the Journal of Power Sources. The National Science Foundation, through Guzman’s graduate research fellowship, supported this work. Frey and Angenent are faculty fellows at Cornell’s Atkinson Center for a Sustainable Future, where faculty engage in cross-campus collaboration.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe