Rapid reality: Students design 3-D printed products

By Anne Ju

Identify a consumer need, design a solution under a certain price, and sell it online.

Those were the basic guidelines this semester for engineering students in Mechanical Synthesis 2250, an introduction to product design. The sophomore-level course, co-taught by mechanical engineering professors Hod Lipson and Zellman Warhaft, took a new twist this year: For the first time, students had their prototype designs printed on Cornell’s brand-new 3-D printers in Upson Hall.

As a final step, students sent their designs to a 3-D printing company like Shapeways or Materialise, where anyone can order and buy the products, custom-printed in materials like food-grade ceramic, metal and plastic.

“It’s really revolutionary in a lot of ways,” said Eric Simeonoglou ’15, whose group made a two-chamber teapot now available for sale on Shapeways. “We were just told to think up something to make – discover a problem that you felt needed to be fixed … and then figure out something you could make to fix it.”

The idea behind the project, called Design, Make, Sell, was to introduce students not only to traditional engineering design, but also to the ways 3-D printing and other desktop fabrication technologies are revolutionizing the design-to-retail process.

Designing, prototyping, manufacturing and retailing typically takes months or even years, Lipson said. But with 3-D printing, it has become possible to greatly speed up this process, going from idea to reality in just a few weeks.

“We can expose students to the entire product design process, including marketing and actually working with real customers, a lot sooner … it’s not a mock homework assignment – it’s the real thing,” Lipson said.

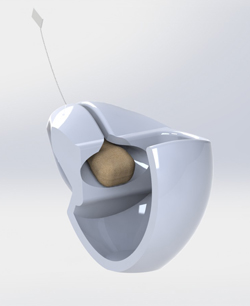

Some products have already turned heads online. The group that made a teacup with a built-in straining system was contacted by a potential investor not long after their design was uploaded to Shapeways, according to group member Amanda Bouman ’15. Their design was also featured on a 3D printing blog.

Just this semester, Cornell received several desktop 3-D printers, including two MakerBot Replicators and two 3D Systems Cubes. Both print objects by depositing streams of fast-hardening molten plastic, layer by layer, from the bottom up. Technician Danny Rocio ’11, M.Eng. ’13, was responsible for taking the students’ computer-aided design (CAD) files and delivering them printed prototypes, which helped the students perfect their designs and prepare the products for sale.

Students came away from the project not only with experience in CAD models and computer programs like SolidWorks, but also with knowledge of marketing and Web design, said Rogerio Bonatti, a Brazilian exchange student studying mechanical engineering at Cornell.

Bonatti called the class one of the best things about his exchange experience, especially because of the exposure to rapid prototyping using 3-D printers. “I think this class is unique in the world and is teaching a technology that will soon be ubiquitous in our lives and in the industry,” he said.

The requirements for the Design, Make, Sell project included a preliminary design review critiqued by peers, an introduction to the basics of 3-D printing and a final design review in which students justified their design choices, decision-making processes and other steps elemental to engineering design. The students were also required to develop marketing strategies for attracting customers.

“I’ve been very positively surprised by what students can come up with once you unleash their creativity with these new manufacturing tools,” Lipson said. “Many students choose engineering because they want to become product designers. Now, they can get a head start.”

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe