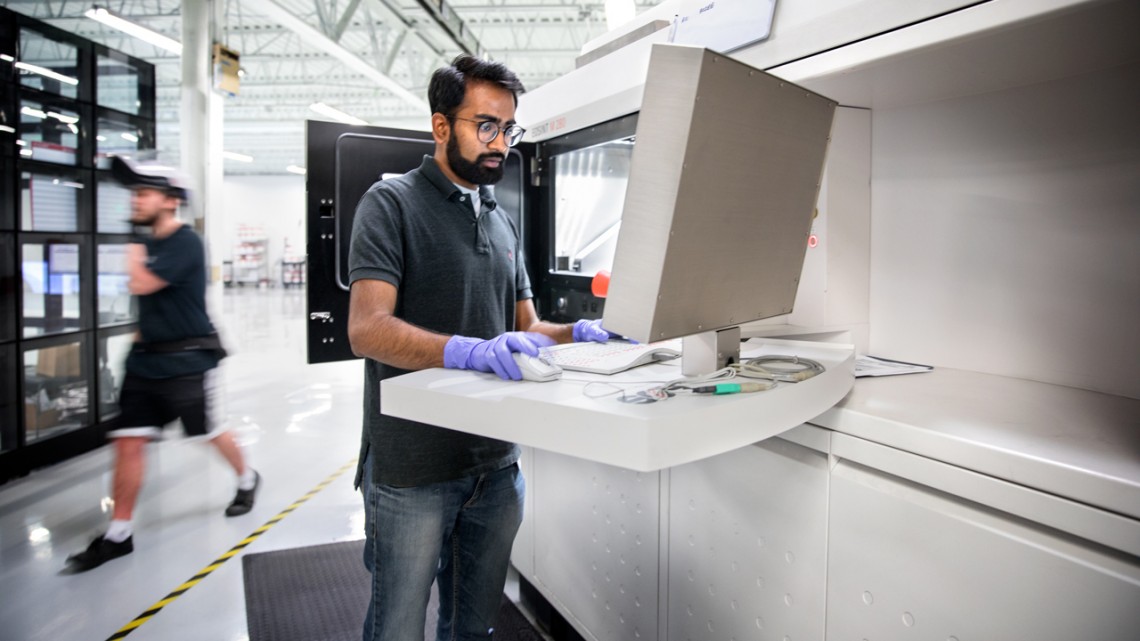

Ajay Krishnan sets up a metal 3-D printing machine for a job at Incodema3D, where Krishnan did his co-op work for the master’s program in materials science and engineering. Krishnan is expecting to graduate this month, and will join the company following graduation.

Materials science master's offers academics along with real-world experience

By Tom Fleischman

Ajay Krishnan knew exactly what he wanted to get with his advanced degree: a high-quality job.

“I was pretty sure that I would be heading to industry after completing a master’s degree and getting some experience,” said Krishnan, who received his bachelor of technology degree in metallurgical and materials engineering from the National Institute of Technology Surathkal, India, in 2016.

When the class valedictorian started scouting programs that featured an industry focus, Cornell’s new master of engineering (M.Eng.) in materials science and engineering (MSE) program stood out – even from 8,000 miles away.

“One thing that appealed to me about the program at Cornell was the fact that there was a lot of flexibility with regard to selecting your courses,” Krishnan said. “You could tailor your curriculum by speaking with your adviser, you could take courses at Johnson (Graduate School of Management), which is something that really appealed to me.”

Krishnan is one of 19 students enrolled in the one-year MSE M.Eng. program, which launched in the 2016-17 school year. A year of classroom study is complemented by a practicum – in an on-campus lab done concurrently with studies or in a paid co-op at one of several local and regional industry partners such as Incodema3D, a leader in metal additive manufacturing, where Krishnan did his.

Generally, students who work off campus have a semester of classroom work, then the practicum, then a final classroom semester.

“One of the biggest benefits of this program is that our students get to apply what they’re learning in the classroom in the real world,” said Alex Deyhim, associate director of the program.

“Another benefit is getting Cornell more involved in the community, specifically having our students contribute on the ground level in local businesses,” Deyhim said. “Our students come from a rigorous technical background and are able to take on projects that have a major impact for our partner companies.”

One of those companies is Sartomer, a supplier of specialty chemicals for 3-D printing, electronics and many other applications. The Philadelphia-based company has benefited from master’s student Weijin Lu’s co-op experience, which began in January.

“He handles a mix of short-, medium- and longer-term projects, some of which are directly based on customer requests,” said Linda Messer, human resources representative for Sartomer. “Weijin continues to add value to our R&D projects, formulating and testing materials as he completes his assignments.”

Combining entrepreneurship, academics

The MSE program brings to 15 the number of master of engineering programs offered at Cornell. Shefford Baker, director of the MSE M.Eng. program, said the MSE faculty were wary of adding the new program at first, fearing it would take focus away from materials science research, where Cornell has a reputation as a world leader.

But the chance to have a tangible, positive effect on students’ lives by giving them real-world experience along with top-quality academics won Baker over. “It’s a chance for us to combine entrepreneurial skills with academic skills,” he said. “Normally, you can’t do that.”

One of the main benefits for students is honing “soft skills” – speaking in front of a group, pitching an idea, dressing for success, even which fork to use and when at the dinner table. All of those lessons are built into the curriculum, and they are invaluable, the students say.

“That [learning soft skills] is probably the thing about this experience that I value the most,” said Andrew Costley, who has had several internships with BorgWarner, including his MSE M.Eng. co-op.

“I’m really benefiting from … learning how to interact with people, talk to people, really stepping out of your comfort zone,” said Mengxue “Hattie” Bi. Her on-campus co-op is with Transonic, an Ithaca-based maker of biomedical measurement devices.

In addition to classroom and practical experience, students gain further polish with related events: a poster session in the fall, a holiday dinner and an awards dinner in May. It’s all aimed at getting students ready to hit the ground running once they’ve secured their degree.

Krishnan’s is a success story: Nearly two years after his arrival at Cornell, Krishnan will graduate with a master’s degree and a job. Incodema3D offered him a materials scientist position, which he will take upon graduation.

“Ajay has been a great asset to Incodema3D,” said Scott Volk, the company’s director of additive technologies and innovation. “He brings knowledge and drive that fills a gap for us as an industry. He has a desire to learn and grow that in nothing short of amazing.”

Krishnan’s story is one that Baker hopes will be duplicated many times over in years to come.

“These students are paying good money for this program, and we want them to get something out of it,” Baker said. “We’ll view the program as a success when both the students and their employers think the M.Eng. degree was well worth the money.”

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe