Vertical gallium oxide transistor high in power, efficiency

By Tom Fleischman

Cornell engineers have made a breakthrough in semiconductor transistor research that offers the potential for high-power electronic applications along with reduced power consumption.

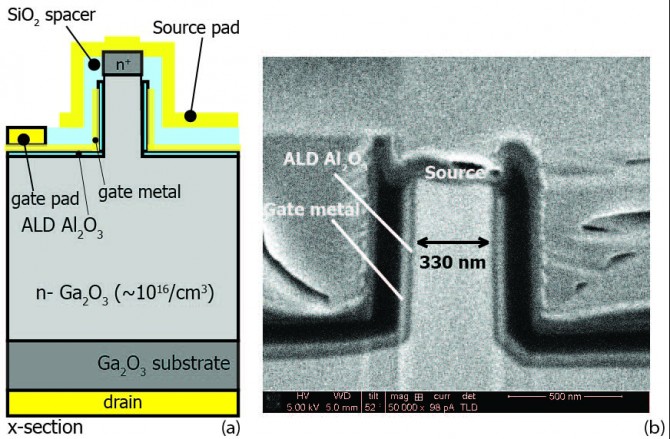

The research has demonstrated metal-insulator-semiconductor field-effect transistors (MISFETs) with record performance using a new material. Gallium oxide has emerged in recent years as a desirable material for semiconductors in high-power applications. Its chief characteristics – a wide bandgap, more than four times that of silicon, and availability of large-area perfect crystals – make it an attractive alternative to silicon for high-power electronics.

Professors Huili (Grace) Xing and Debdeep Jena from the departments of Electrical and Computer Engineering (ECE) and Materials Science and Engineering (MSE) presented a series of these findings at the annual Compound Semiconductor Week (CSW) held in Boston May 29-June 1. The record performance device results were published April 25 in IEEE Electron Device Letters, in a paper titled “Enhancement-Mode Ga2O3Vertical Transistors With Breakdown Voltage >1 kV”.

Zongyang Hu, a postdoctoral researcher in the Jena-Xing Group, is the lead author. Also contributing were research associate Kazuki Nomoto, doctoral students Wenshen Li and Nicholas Tanen as well as researchers from Hosei University, Tokyo, and Novel Crystal Technologies of Japan.

Enhancement-mode operation – the most desired switching characteristic in metal-oxide semiconductor transistors, in which the device is in the “off” state at zero volts – is attractive in power electronics applications to avoid catastrophic failure in the event of loss of control. A depletion-mode device is in the “on” state at zero volts, and more prone to failure than the enhancement-mode transistor.

The group used hydride vapor phase epitaxy to deposit a 10-micron layer of silicon-doped gallium oxide onto a gallium oxide single-crystal substrate. A micron is one-millionth of a meter.

Their methods and measurements, detailed in the paper, produced a vertical power, enhancement-mode MISFET that featured breakdown voltages – the minimum voltage that causes a portion of an insulator to become electrically conductive – of greater than 1,000 volts, as well as an attractive on/off ratio (the difference between on-state current and off-state current).

According to the paper, gallium oxide’s expected critical electric field exceeds that of silicon and gallium nitride. Xing said her group’s MISFET could be good for harsh-environment electronics.

“Say you wanted to drill for oil,” she said. “You want to have sensors right next to your drill bit to know the temperature, the mechanical stress where you’re drilling. Your sensor needs to be able to handle the high temperature.”

Xing was the technical program chair for the CSW conference, which was held at Massachusetts Institute of Technology. Jena was a member of the organizing sub-committee related to the gallium oxide focus session, at which seven members of their joint group presented their research results on a wide range of materials and devices.

Support for the published research came from the National Science Foundation and the Air Force Office of Scientific Research. This work was performed in part at the Cornell NanoScale Science and Technology Facility, which is supported by the National Science Foundation.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe