Scientists find new ways to harvest commercial amounts of potential drug-grade proteins

By Blaine Friedlander

They go from bugs to drugs. Thanks to the confluence of a new technology in virology and a recent patent in rearing insects, scientists at the Boyce Thompson Institute for Plant Research Inc. (BTI), located at Cornell University, have found a better way to produce commercial quantities of recombinant pharmaceutical proteins -- out of insect larvae.

"These are valuable proteins, and they can't be produced this well any other way," said H. Alan Wood, a virologist at BTI. "Essentially, this is a protein factory. We are using insects to raise raw pharmaceutical proteins. In effect, we are turning insects into little protein factories."

Originally, the researchers were exploring ways to safely combat agricultural pests through biological means, but in their research they learned that the proteins from these nearly dead pests could directly benefit humanity. Recombinant baculoviruses have been used before to develop a panorama of pharmaceutical proteins but were made using the insect cell culture method, a time-consuming, and expensive process.

Scientists can harvest the beneficial protein from the infected larvae of lepidoptera -- moths and caterpillars. Genetically engineered baculoviruses, which are viruses shaped like rods, attack the inside of the larvae, initiate a wholesale, metabolic change and kill the insect.

"The baculovirus literally turns the insect to liquid," said Patrick R. Hughes, BTI researcher. "Right before the insect dies, we harvest the protein, and the protein can be refined into pharmaceuticals."

The virus spreads through the caterpillar within 24 hours, but the bug continues to grow, spreading virus through the caterpillar's body for three days. Just prior to the fourth day, or the fifth larval stage, the proteins being grown in the bug are ready for harvest. Hughes says the bug never reaches pupation, and if the protein is not harvested from the caterpillar during this crucial larval stage, the proteins are destroyed.

Farming the pharmaceuticals becomes easy using a recently patented system called HeRD -- the high-efficiency rearing device. Developed at BTI, HeRD can raise thousands of insects all at once to produce protein, thus reducing the expense. Using the HeRD system, the BTI researchers are growing caterpillars -- Trichoplusia ni -- a pest best known as the cabbage looper, which feeds on cabbage, cotton and crucifers.

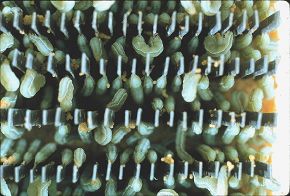

But the insects are living on the edge. "Patrick [Hughes] is a very observant man and because he's observant, he came up with a brilliant idea -- the HeRD system," Wood said. What Hughes observed is that insects prefer getting their footing on the edges of surfaces, not directly on flat surfaces. Hughes developed a box full of close-spaced pillars -- pillars shaped like small popsicle sticks -- and puts the insects in the box. He also put food in the box. The insects are reared on the pillars in the box, making it easy to infect them with baculovirus and then harvest the proteins.

In the past 18 months, researchers report that recombinant baculovirus have been used for vaccine production. Some of the diseases that can be fought include human papillomavirus, human T-cell leukemia virus, hepatitis-C virus, Norwalk virus, rotavirus, porcine parvovirus and African swine fever virus. BTI researchers do not directly study these diseases.

Producing proteins through insects was seen as an alternative to raising proteins in cell culture, Hughes said. For a while, it appeared as if raising the proteins in cell culture was less expensive, but rearing proteins in insects is substantially less expensive than cell cultures. "We don't have the many technical barriers we had before," he said.

Hughes and Wood have published their presentation, "Recombinant Viral Insecticides: Delivery of Environmentally Safe and Cost-Effective Products," in the July 24, 1997, edition of the journal Entomophaga, the publication of the International Organization for Biological Control of Noxious Animals and Plants.

In addition to pharmaceuticals, the researchers said that the technologies involved could be used for other purposes, like manufacturing inexpensive viral insecticides as alternatives to pesticides. Wood and Hughes said that with more than 30,000 chemical pesticide registrations being canceled in the past eight years, there is a need to develop natural and genetic baculoviruses. The researchers believe that to make these insecticides commercially viable, methods like HeRD will need to be employed to bring costs down.

BTI, the Boyce Thompson Institute for Plant Research Inc., is the largest non-profit, independent plant research facility in the world. It was founded in 1924, by Col. William Boyce Thompson in Yonkers, N.Y. The purpose of the institute was to find ways to meet the food and health needs of an increasing world population. BTI moved to the Cornell campus in 1978.

Get Cornell news delivered right to your inbox.

Subscribe