Microscopic beads help harvest heparin

By Blaine Friedlander

Cornell scientists have created microscopic beads that efficiently recover heparin, an ingredient used as a pharmaceutical blood thinner, from agricultural animals. The new process creates less environmental waste, according to new online research in Chemical Engineering Journal.

Doctors use heparin sodium as a blood thinner, anticoagulant and heart disease medicine as it staves off clotting, said chemist Alireza Abbaspourrad, the Yongkeun Joh Assistant Professor of Food Chemistry and Ingredient Technology.

Scientists have been unable to produce the chemical synthetically.

“The main source of heparin is from the inner intestinal mucosa from cows and pigs. If you don’t capture it all, the rest goes into the waste stream. We are trying to become more efficient trying to capture it,” Abbaspourrad said.

Currently, after a cow or pig is slaughtered for its meat, polymeric resins are used to extract heparin from mucosa, but the resin used in this process is not efficient, collecting only a fraction of the heparin that exists in mucosa.

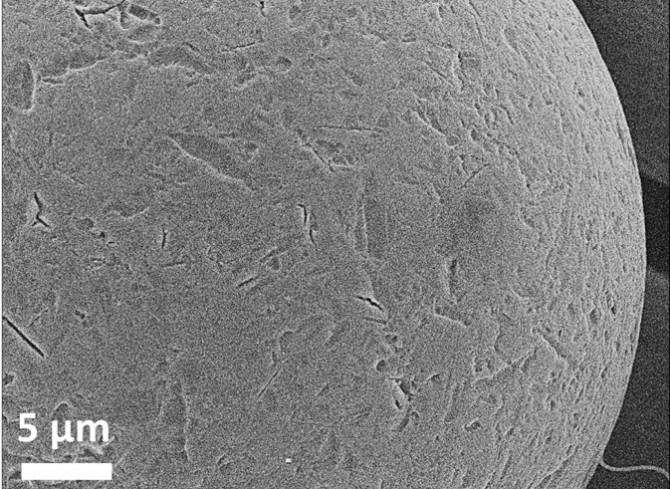

In this research, the scientists replaced the resin with tiny, porous polystyrene beads coated with chitosan, a heparin-attracting chemical powder derived from the shells of shrimp. This resulted in a much more efficient process.

“We designed the microbeads to attract heparin better,” said Abbaspourrad. “This is a better, more efficient way to capture it. We sought a sustainable way to recover as much as we can, nearly 100 percent of the heparin found in the mucosa of the intestine.”

In addition, many impurities can be found in the mucosa. “There are lots of natural things inside that goop,” said Abbaspourrad. “So we designed the beads to like heparin the most.”

The fabricated microbeads are capable of excellent adsorption (soaking up) of heparin, higher than what is now commercially available, and the beads can be applied to heparin recovery at an industrial scale, said lead author Hamed Eskandarloo, a postdoctoral researcher in Abbaspourrad’s laboratory group.

“We compared the cost of the microbeads and a currently available chemical resin, and we believe the beads represent significantly lower costs,” said Eskandarloo. “Fabricated microbeads are easy to prepare in large quantities, and they can be manufactured inexpensively. This provides an adsorbent (characteristics of a sponge) in the scalable recovery of heparin in porcine intestinal mucosa.”

Other co-authors of “Multi-Porous Quaternized Chitosan/Polystyrene Microbeads for Scalable, Efficient Heparin Recovery” are doctoral candidate Mary Godec; postdoctoral researcher Mohammad Arshadi; and Olga I. Padilla-Zakour, professor and chair of Cornell’s Department of Food Science.

The Abbaspourrad group used the Cornell Center for Materials Research, which is supported through National Science Foundation funding. Other research funding was provided by the Shineway Group.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe