News directly from Cornell's colleges and centers

Fix discovered for elusive gallium-oxide contact problem

By Syl Kacapyr

Cornell researchers have uncovered a nearly invisible culprit hindering the development of next-generation, high-power electronics: a microscopic layer of carbon contamination, often left behind by air exposure and fabrication techniques, that impairs electrical flow in devices made with gallium oxide. They have also found a solution.

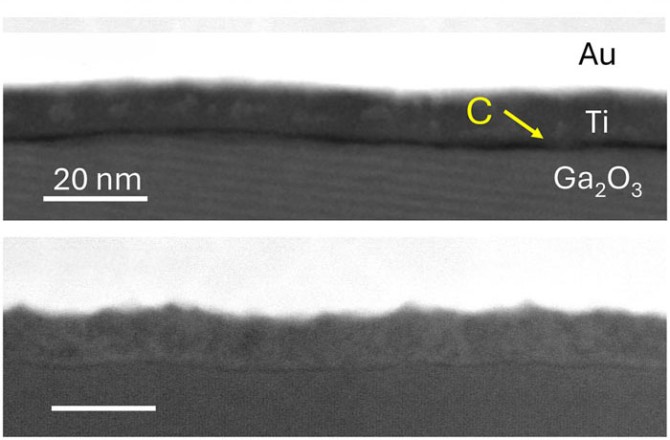

A study published June 20 in the journal Applied Physics Letters is among the first to directly visualize this nanometer-thin barrier that can occur when metals are patterned onto semiconductors, an essential interface for getting current in and out of electronic devices. When these contacts have resistance, device performance suffers.

The challenge is especially pronounced in beta gallium oxide, a semiconductor material with an ultra-wide band gap that could one day allow devices like electric vehicles and grid infrastructure to more efficiently handle higher voltages.

“It’s been a problem in the gallium oxide field for quite some time,” said Naomi Pieczulewski, a doctoral student in materials science and engineering and the study’s co-lead author. “Sometimes you get good conduction and sometimes you get absolutely no conduction at all, and no one could really pinpoint why.”

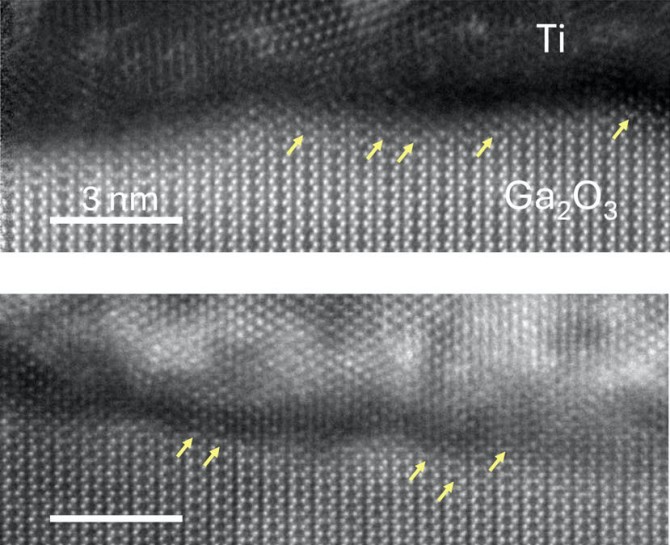

Pieczulewski’s research spans multiple Cornell labs uniquely positioned to investigate the problem, including one specializing in production of oxide materials and one specializing in atomic-resolution microscopy. Focusing on the interface between a beta gallium oxide and titanium contact, Pieczulewski and colleagues used scanning transmission electron microscopy and other techniques to compare two common methods for fabricating the contact: a traditional lift-off process, and a metal-first process in which metal is deposited before the semiconductor is patterned.

In the lift-off samples, the researchers observed a thin, patchy layer of carbon between the metal and the semiconductor leftover from photoresist materials used during processing. To tackle the contamination, a one-hour UV-ozone exposure effectively removed the carbon layer, enabling a contact resistance as low as 0.05 ohm-millimeters, among the lowest reported for non-alloyed beta gallium oxide contacts.

Carbon contamination resulting from air exposure in the metal-first fabrication method was remediated with a five-minute active oxygen treatment, significantly lowering the contact resistance and improving current flow.

“This research enables a way to produce reliable, consistent ultra-wide bandgap devices,” Pieczulewski said. “It's an incremental progress for making ohmic contacts, but I think it's significant in terms of moving toward commercialization.”

The study’s other co-lead author is Kathleen Smith, Ph.D. ’24. Corresponding authors include Huili Grace Xing, the William L. Quackenbush Professor of Electrical and Computer Engineering and of Materials Science and Engineering; and David Muller, the Samuel B. Eckert Professor of Engineering in the School of Applied and Engineering Physics.

The study was the first to unite on one research paper all seven co-principle investigators of the AFRL-Cornell Center for Epitaxial Solutions, also known as ACCESS, which along with Xing and Muller include Debdeep Jena, the David E. Burr Professor of Engineering; Michael Thompson, the Dwight C. Baum Professor in Engineering; Darrell Schlom, the Tisch University Professor; Farhan Rana, the Joseph P. Ripley Professor of Engineering; and Hari Nair, assistant professor of materials science and engineering.

Boise State University and Micron, through the Semiconductor Research Corporation (SRC), contributed advanced characterization techniques to the study.

The research was supported in part by the ACCESS Center of Excellence, funded by the Air Force Research Laboratory, and the SUPREME Center funded by SRC and DARPA. Device fabrication was performed in part at the Cornell NanoScale Science and Technology Facility and the Cornell Center for Materials Research, both funded by the National Science Foundation.

Syl Kacapyr is associate director of marketing and communications for Cornell Engineering.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe