Christopher J. Hernandez, associate professor in the Sibley School of Mechanical and Aerospace Engineering and in the Meinig School of Biomedical Engineering, explains how seemingly minor aspects of the internal structure of bone can be strengthened to withstand repeated wear and tear from cyclic loading.

Bone breakthrough may lead to more durable airplane wings

By David Nutt

Cornell researchers have made a new discovery about how seemingly minor aspects of the internal structure of bone can be strengthened to withstand repeated wear and tear, a finding that could help treat patients suffering from osteoporosis. It could also lead to the creation of more durable, lightweight materials for the aerospace industry.

The team’s paper, “Bone-Inspired Microarchitectures Achieve Enhanced Fatigue Life,” was published Nov. 18 in the Proceedings of the National Academy of Sciences.

For decades, scientists studying osteoporosis have used X-ray imaging to analyze the structure of bones and pinpoint strong and weak spots. Density is the main factor that is usually linked to bone strength, and in assessing that strength, most researchers look at how much load a bone can handle all at once.

But a team led by senior author Christopher J. Hernandez, associate professor in the Sibley School of Mechanical and Aerospace Engineering and in the Meinig School of Biomedical Engineering, is interested in long-term fatigue life, or how many cycles of loading a bone can bear before it breaks.

“The best way to understand the fatigue properties of material is to think about a part in your car that breaks every so often, so you have to take it to the shop. Well, why did it break? It was clearly strong enough, because it worked for months, years, just fine. But after cycling and cycling and cycling, tens of millions of cycles, it breaks,” Hernandez said. “We’ve known about this property of materials for 150 years, and it’s embedded in the design of everything we do. But not too many people had done this kind of study of the bone.”

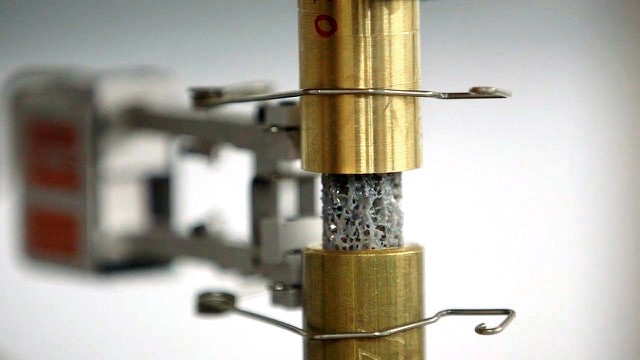

The internal architecture of bone consists of vertical plate-like struts that determine its strength when overloaded. The bone also has horizontal rod-like struts, which have little influence on strength and are essentially “window dressing.” Hernandez and his team suspected that other aspects of architecture were important. Using new computer software, lead author Ashley Torres, M.A. ’15, Ph.D. ’18, MBA ’19, was able to perform a deeper analysis of a bone sample and found that, when it comes to withstanding long-term wear and tear, the horizontal rod-like struts are critical for extending the bone’s fatigue life.

“If you load the bone just once, it’s all about how dense it is, and density is mostly determined by the plate-like struts,” said Hernandez, who is also an adjunct scientist at the Hospital for Special Surgery, an affiliate of Weill Cornell Medicine. “But if you think about how many cycles of low-magnitude load something can take, these little sideways twiggy struts are what really matter. When people age, they lose these horizontal struts first, increasing the likelihood that the bone will break from multiple cyclic loads.”

The team used a 3D printer to manufacture bone-inspired material made from a urethane methacrylate polymer. The researchers varied the thickness of the rods and were able to increase the material’s fatigue life by up to 100 times.

Hernandez anticipates the reinforced microstructure lattices his team developed could be incorporated into just about any device, and would be particularly beneficial to the aerospace industry, where ultra-lightweight materials need to withstand tremendous and repeated strain.

“Every wind gust that an airplane hits causes a cycle of loading on it, so an airplane wing gets loaded thousands of times during every flight,” Hernandez said. “If you want to make a durable device or a vehicle that is lightweight and will last a long time, then it really matters how many cycles of loading the part can take before it breaks. And the mathematical relationship we’ve derived in this study lets somebody who’s designing one of these lattice structures balance the needs for stiffness and strength under a single load with the needs for tolerating many, many lower-level load cycles.”

Co-authors include Cornell doctoral students Cameron Aubin and Marysol Luna; postdoctoral researcher Floor Lambers; Pablo Zavattieri and Adwait Trikanad at Purdue University; and Clare Rimnac at Case Western Reserve University.

The research was supported in part by the National Institute of Arthritis and Musculoskeletal and Skin Diseases of the National Institutes of Health; the National Science Foundation through a Graduate Research Diversity Supplement and CAREER award; and a Cornell-Colman fellowship that aims to broaden representation and develop future engineering leaders.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe