When bad makes good: Defects strengthen 3D-printed material

By David Nutt

Sometimes it’s good to be a little bad.

Cornell researchers found a counterintuitive way of improving 3D-printed metal alloys. By deliberately introducing more defects into the printing process, followed by a post-processing treatment that uses high temperature and high pressure to change the material’s microstructure, they turned the defects into assets, resulting in a stronger, more ductile metal product.

The technique could potentially be applied to any 3D-printed metal alloy and could be particularly effective for manufacturing products for biomedical and aerospace industries.

The group’s paper, “Exploiting Lack of Fusion Defects for Microstructural Engineering in Additive Manufacturing,” published Oct. 19 in Additive Manufacturing. The paper’s lead author is doctoral student Jenniffer Bustillos, a 2020-21 graduate fellow with the Kavli Institute at Cornell for Nanoscale Science.

“One of the major challenges in additive manufacturing are the defects that are being generated during the process,” said Atieh Moridi, assistant professor in the Sibley School of Mechanical and Aerospace Engineering, and the paper’s senior author. “For such a long time, everybody – including myself – has been focusing on eliminating those defects. And this is not a trivial task. So we asked ourselves: What if we try to use those defects that are generally considered a limitation for additive manufacturing and turned them into the strengths of additive manufacturing?”

Two major processes are used for 3D printing metals: powder bed fusion, in which powder is layered on a substrate and bonded or melted, and powder fed, whereby the powder is applied via nozzle and melted by beam.

Both processes result in defects, essentially tiny pores, which weaken the material. Manufacturers have tried a variety of methods to avoid introducing these flaws, from altering the material’s chemical makeup to applying external stimuli, such as ultrasound, during the printing process. However, those methods are not easily transferable from one printing process to another, or from one material to another, Moridi said.

Troublesome as they are, material defects have a secret advantage: They contain a lot of energy. Moridi’s group realized they could harness that energy and put it to good use. And they broke a few rules along the way.

“Normally we try to optimize process parameters to minimize the defects,” Moridi said. “But here we intentionally used no optimized parameters. We actually did a lousy printing to add more of those naturally occurring defects.”

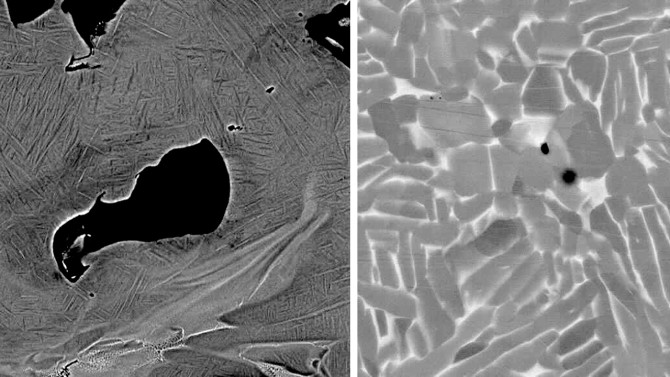

The group 3D-printed a titanium alloy, Ti-6Al-4V. Once they had their defect-riddled sample, they applied an extra post-processing step called hot isostatic pressing (HIP) in which the metal was treated with extreme heat and pressure simultaneously. The pressure forced the pores, which naturally have a high stress concentration, to close up, while the temperature pushed the pores’ excessive energy to change the material’s internal structure. That combination gave the alloy a binary, or hybrid, microstructure and it functions much like a composite material. And it proved to be stronger and more ductile than other titanium printed metals.

“We were able to achieve properties that were better than traditional manufacturing techniques, like casting and forging,” Moridi said. “It was exciting to see how, with a simple trick, we could get to those properties.”

The researchers’ defect-centric technique can be used for both powder-bed and powder-fed processes. And in an unexpected benefit, the change in microstructure broke the directionality of the material’s crystals, turning them isotropic, meaning the properties apply in all directions, whereas most printed materials have a strong direction and a weak direction.

“When we have these kind of directional crystals, they are more susceptible to solidification cracking because they can’t accommodate stress very well,” Moridi said. “But ours are smaller and more isotropic. They have a much easier time rotating and accommodating the internal stresses that are developed during the printing process.”

Moridi’s group is now exploring ways to reduce the chance of fatigue failure, which is a risk when residual defects have not fully healed.

“This is a fairly simple process,” Moridi said, “and one we can learn from to turn our weaknesses into strengths.”

Former postdoctoral researcher Jinyeon Kim contributed to the research.

The research was supported by the Kavli Institute’s Knight Family Foundation Graduate Fellowship in Nanoscience and Technology. The researchers partnered with the companies Open Additive and Quintus Technologies for the fabrication of the material and the hot isostatic pressing, respectively. The team also made use of the Cornell Center for Materials Research, which is supported by the National Science Foundation.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe