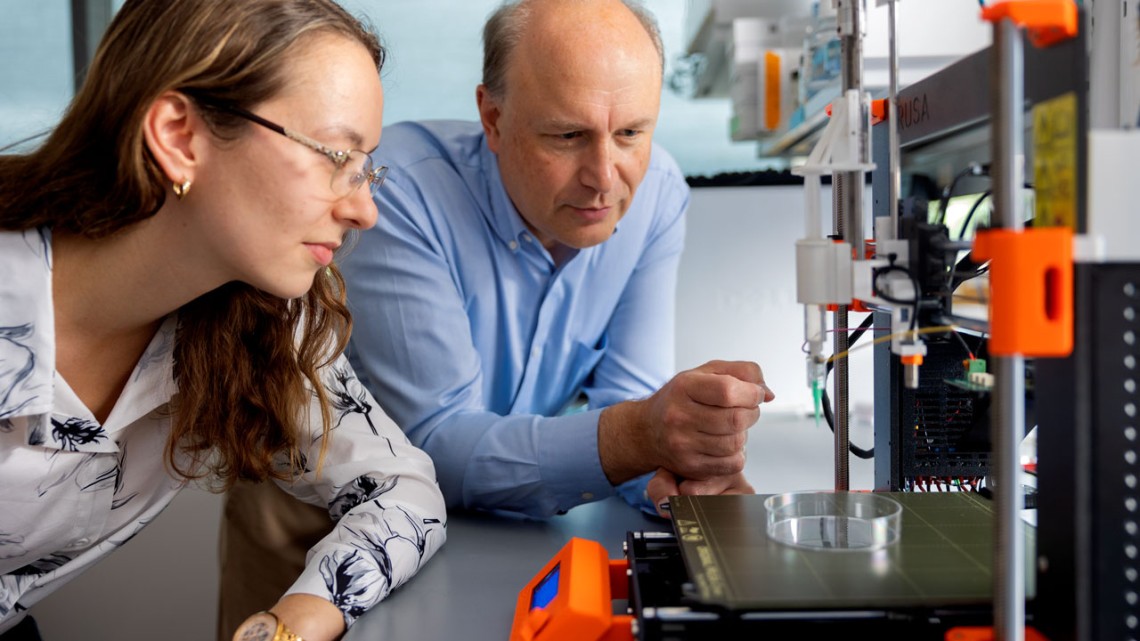

Lawrence Bonassar, the Daljit S. and Elaine Sarkaria Professor in Biomedical Engineering and in Mechanical and Aerospace Engineering, and doctoral student Alicia Matavosian examine a smart sensor developed with Jared Matthews ’21.

From lab to patent: Undergrad creates smart syringe for bioprinting

By David Nutt, Cornell Chronicle

Sometimes a researcher goes into the lab and comes out with a discovery. Sometimes that discovery is issued a patent. Very rarely does the process also involve an undergraduate, a potential breakthrough for biomedical printing and cell therapy, and a little help from Bill Nye ’77 the Science Guy.

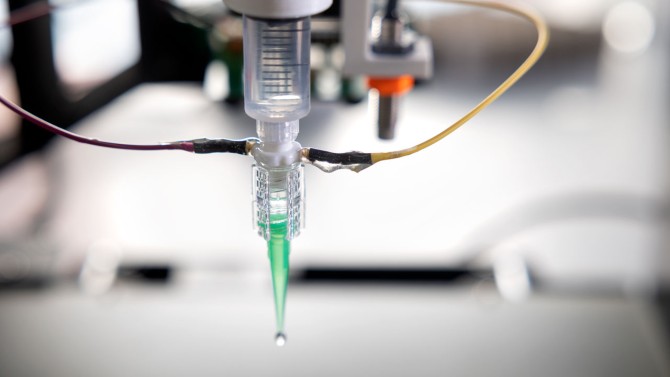

As an ambitious sophomore, Jared Matthews ’21 was looking for a research project and he approached Lawrence Bonassar, the Daljit S. and Elaine Sarkaria Professor in Biomedical Engineering and in Mechanical and Aerospace Engineering in Cornell Engineering. Together they created a smart sensor that attaches to the tip of a syringe to measure, in real time, the concentration and viability of the cells that pass through it – a device that would enable surgeons and biomanufacturers to produce higher quality implants of living tissue, even organs.

“A lot of inventions come out of this university,” Bonassar said. “Not a lot of them involve undergraduates, and not a lot of them happened during COVID. Most of our peers didn’t even have undergraduates on campus in fall 2020. And here we have an undergraduate not only on campus, but working in a lab and inventing and patenting something that could be really impactful.”

For two decades, Bonassar’s lab has been making bioprinting technology that combines cells with materials such as hydrogel ink to fabricate new living tissues and organs that function better than inanimate implants. But in bringing this technology from the lab to the clinic, one persistent problem has remained.

“One of the real challenges in manufacturing is the quality control,” Bonassar said. “If you’re going to print something that’s alive with cells in it, the first thing you need to know is how many cells are in it? And what fraction of them are alive?”

Previous attempts to make those types of measurements with bioprinting have relied upon optical detectors, which measure the light reflected off cells as they are squeezed through a channel. However, such approaches require the concentration of cells to be low, greatly limiting the range of applications to which this idea is applicable and stymieing attempts to construct anything with a high cell density, such as organs. And it couldn’t be done in real time.

‘A crazy idea’

When Matthews arrived at Cornell as a freshman, he already had a field of interest – biomedical engineering – and a head start on research. During his senior year of high school in central Massachusetts, he’d worked for Washington University professor Farshid Guilak, analyzing computed tomography images of biological samples and building specialized lab apparatuses that combined CAD software and 3D printing.

Upon being accepted to Cornell, Matthews visited campus in April 2017, and he made a bold move. He stopped by the office of Guilak’s close colleague, Larry Bonassar.

“I was like, man, I should probably start to network a little bit. I thought I was being clever,” Matthews said. “It was early morning, and he happened to be in his office. We sat down and talked for an hour or two, which, you don’t know when you’re 18, but that’s a huge commitment for a professor. And I guess it was a sign of what was to come.”

Two years later, as a sophomore mechanical engineering major, Matthews came back to Bonassar with a specific ask. Was there a research project Matthews could work on?

What Bonassar had, in his own words, was “a crazy idea” that he’d been kicking around for a long time but hadn’t been able to investigate. While his lab had successfully demonstrated 3D printing living tissue with homogeneous materials for replacement ears and cartilage, the next step was doing that for more sophisticated, functional structures, i.e., organs and skin.

The project had a greater scope than what an undergrad would traditionally tackle, but Matthews found the challenge compelling. That’s not to say it wasn’t a little daunting.

“It was my first experience really reading a research paper,” Matthews said. “I didn’t know what I was reading. But I was like, you know, I’m gonna try it.”

Developing a new method wouldn’t just be an academic exercise, he recognized, but a “very applied, practically useful device, with implications in industry for manufacturing tissue at scale.”

Bonassar and Matthews brainstormed ideas and hit upon an alternate mode of sensing: dielectric impedance spectroscopy (DIS), whereby a pair of electrodes creates a current. Because cell membranes are not permeable to charge, the current would be forced to go around the cells as their internal ions became polarized. That combination of effects would create a unique impedance signature for each cell that could ultimately be measured to determine the number of cells and their size, intactness and density.

It was a smart design, indeed. It just needed to be built. And tested. And studied.

Because Matthews was deep in his undergraduate studies, he didn’t have much free time during the semester to get the project off the ground. So he applied for, and received, a grant from Engineering Learning Initiatives to work in the lab through the summer of 2019.

In addition to covering his living and research expenses, the grant carried some extra cachet. It came from a donation made by Bill Nye.

As the 2019 Nye Fellow, Matthews had an opportunity to meet the “Science Guy” himself that summer and tell him a bit about the smart syringe and its potential impact.

“He said, ‘Well, go on and change the world.’ It left an impression on me, for sure,” Matthews said. “That was a great little introduction to my research work, to have a celebrity backing it.”

‘Something kind of special’

By the end of fall 2019, Matthews had constructed a protype, conducted the initial experiments and presented the work-in-progress to the Biomedical Engineering Society in Philadelphia. But the ensuing months would not go as smoothly. In March 2020, the pandemic hit, derailing all on-campus research and activities. So Matthews pivoted and focused on data analysis and reviewing the relevant literature to put his experimental results in context.

“You don’t just get a yes or no answer from the device. It doesn’t just tell you if it worked or not. You get back waveforms, signal, there’s going to be noise, artifacts, and you have to interpret that in the context of the physical chemistry and the algorithms you used to process it,” Matthews said. “It was not a pure mechanical engineering problem. It pulled from so many different fields. You had to know, at some level of competency, control theory, and interface theory from chemistry, fluid dynamics. All these disciplines came together, and you had to be able to attend to them individually.”

By the time Matthews was ready to graduate, in spring 2021, “we knew we had something kind of special,” Bonassar said. “That’s when we disclosed it to Cornell and filed the provisional patents.”

Within three years of submitting their application, the patent was issued in June. By Bonassar’s count, this is his 25th patent. He’s never had one approved so quickly.

“We’ve had patents that have taken us seven years to get through the process. For people in the know, two to three years from initial application to issue is quite fast,” he said. “What that often means is there isn’t much like it, and we didn’t get hit with, ‘Oh, it looks like seven other people have tried things like this, why is yours different?’ My impression is there’s really not much out there where people are doing assessment of cell properties at these really high concentrations.”

In addition to capturing 2,000 different measurements in real time, the device creates a series of feedback loops that can help control the flow rate and temperature as cell viability changes. That in itself would be revolutionary for the bioprinting field, but the device has applications in other fields as well. Hospitals in developing countries could use it for getting instant blood counts on patients. Doctors could deliver precise infusions of cells, bone marrow and lipos for cell therapy, treating cancer or for regenerative medicine.

“If we can measure it, then instead of saying, ‘Well, deliver 10 CCs of this solution that we think has a million cells per CC,’ you can now make a device that just delivers 10 million cells and then stops,” Bonassar said.

Bonassar’s lab has collaborated with Dr. Jason Spector, professor of plastic surgery at Weill Cornell Medicine, to demonstrate how the smart syringe can assist in clinic samples.

After Matthews graduated from Cornell, he headed to Georgia Tech, where he extended what he had learned from the smart syringe project into developing more next-generation medical devices, such as soft, wearable biosensors and remote telemedicine platforms for optimizing strength and metabolism, and cardiovascular monitoring. Even when the technology was different, the underlying skills were the same: problem solving, interpreting data, presenting findings to a skeptical audience.

That research experience, in turn, led him to his current role working for GE HealthCare, developing large neural networks for optimizing patient care.

Now, he and Bonassar are mulling their options to commercialize the smart syringe, although in many ways, it’s already been a success.

“I wouldn’t be here, privileged to do what I do, without having worked on the smart syringe project, specifically with Larry,” Matthews said. “He grants a lot of autonomy, he trusts in his students, and that comes through to the student. Larry was always there as a fallback to help steer the project when it began to drift. I remember he said a design I had was ‘orthogonal,’ meaning it was perpendicular to the direction we should be going. I had never had anyone tell me that before. It was delivered so well, I wasn’t upset by it. It was like, OK, let’s try something different. It was sort of a humbling experience in that way.”

The time he spent in Bonassar’s lab paid off in other ways, too. That was where, in the summer of 2019, he first met another undergraduate researcher, Emily Jiang ’20.

She is now his fiancée.

“That’s a little happy ending there,” Matthews said.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe