Team to design 3D-printable mask inspired by animal noses

By Krishna Ramanujan

A multi-institution team, including a Cornell researcher, has received a National Science Foundation grant to design an open-source, 3D-printable medical mask inspired by the nasal structures of animals.

The team has been awarded a special one-year, $200,0000 RAPID grant; co-principal investigator Sunghwan “Sunny” Jung, associate professor of biological and environmental engineering, will receive $75,000 of the total to design the mask.

The researchers plan to release their open-source design within 10 months and then disseminate it for the remaining two months. By providing a template for use with 3D printers, the researchers hope their design addresses mask shortages and improves existing face protection.

“The current COVID-19 outbreak shows there is a national shortage of medical masks,” Jung said. “We need to be more flexible. Our mask will use the 3D printer – and at this time a lot of people have a 3D printer at home.”

The other principal investigators are Leonardo Chamorro, associate professor of mechanical science and engineering at the University of Illinois, Urbana-Champaign, and Saikat Basu, assistant professor of mechanical engineering at South Dakota State University.

Current protective masks are made with a fine mesh, but the pathogens can live on these surfaces after they are used. Jung’s design will use a 3D printable mesh material that incorporates copper, which kills viruses on contact.

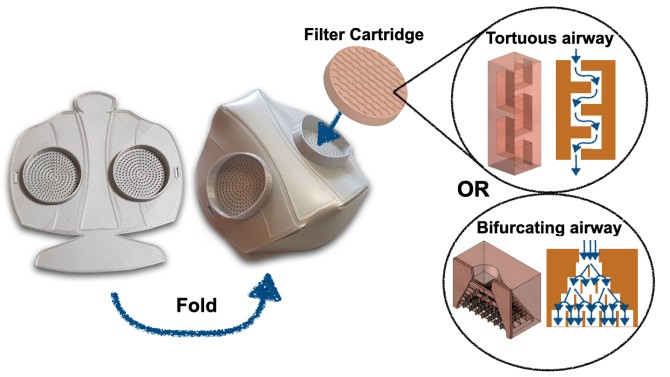

Animals with extremely sensitive noses, such as dogs and rats, have nasal structures with two features for capturing molecules: The air passageways in dogs, for example, branch to create many smaller air ducts; those passages are also tortuous, or maze-like. These features create increased surface area and curvature to capture molecules and other particles on passage walls.

While animal noses combine these features, Jung will initially create two separate designs for testing, one with ducts that branch into smaller and smaller airways and another with tortuous, winding air passages. Chamorro will handle the physical testing and visualizing particles in the air passageways, while Basu will do computational simulations to see how effective each of these air passage designs are at collecting a virus or aerosol.

To design the mask, Jung has formed a team of students: Anuj Baskota ’21, Ben Cooke ’21, master of engineering student Karl Frolich and doctoral student Jisoo Yuk. The team has worked to understand animal nasal structures and how to simplify these air flow passageways for use with 3D printers.

When done, the team plans to include other mask designs for people with limited resources or who lack access to a 3D printer. Though the open-source design will be free, the team intends to file for patent protection.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe