Nonalcoholic beer at higher risk for foodborne pathogens

By Blaine Friedlander, Cornell Chronicle

The lack of alcohol in nonalcoholic or low-alcohol beer – particularly during manufacturing, storage and pouring – may prompt conditions ripe for foodborne pathogen growth, according to a new Cornell study.

The absence of physical hurdles for microbes to take over the beverage may render these brews susceptible to bacteria and other spoilage problems, the researchers found.

“When you remove the alcohol, it’s really no longer a traditional beer,” said Randy Worobo, professor of food science in the College of Agriculture and Life Sciences and senior author of “Survival of Foodborne Pathogens in Low and Nonalcoholic Craft Beer,” publishing December 2023 in the Journal of Food Protection. “We suspected that foodborne pathogens would be able to grow without the presence of alcohol. We were correct. At that point, you must consider nonalcoholic beer like food and make sure that all parameters are met guaranteeing product safety.”

Doctoral student Mario Çobo conducted the research in Worobo’s laboratory.

Traditional beers – which can be up to 10% alcohol by volume – contain low pH, harbor a presence of ethanol, provide acid from the hops and keep little oxygen, all of which contribute to microbial stability. In fact, for beer wort boiling (the watery grain simmer that starts the brewing process), the natural pasteurization, filtration and cold storage contribute to pathogen safety as well, according to the paper

“Craft manufacturers of nonalcoholic beer sometimes follow a traditional beer making process,” said co-author Ann Charles Vegdahl, an extension associate in the Department of Food Science at Cornell AgriTech in Geneva, New York.

For example, hopping beer – the process of adding hops during the fermentation or conditioning process – has become a popular brewing method for regular alcoholic beers over the past two decades. In fact, the scientists said, that is how India Pale Ale originated to solve spoilage issues during longer ship voyages.

To boost flavor, hopping can be applied to nonalcoholic brews. “But in the end,” Charles-Vegdahl said, “brewers add additional material for flavoring and aroma – like hops – to nonalcoholic beers, which could potentially introduce contamination.”

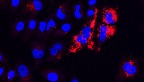

The scientists inoculated samples of nonalcoholic beer with the bacteria E. coli O157:H7, Salmonella enterica and Listeria monocytogenes, then stored the beverages at two different temperatures (39 and 57 degrees Fahrenheit) for two months. The pathogens grew and survived.

In the low-alcoholic beer, the added E. coli O157:H7 and S. enterica doubled when stored at 57 degrees F, but Listeria was undetectable at both temperatures and all conditions.

Acids also help beer counter pathogens. Çobo said beers with high pH, greater than 4.60 pH, plus low- to no-alcohol and low carbon dioxide – were more susceptible to spoilage.

Due to the increased susceptibility to spoilage and pathogens, the formulation of these beverages must be evaluated for safety by a food processing authority, the researchers said. Low and nonalcoholic beers should be processed through pasteurization, to achieve commercial sterility. Sterile filtration and the addition of preservatives should be considered as additional steps to reduce this microbial risk.

The researchers said that due to increasing consumer demand for nonalcoholic beer served on draft – or poured from a keg, for example – also could boost microbial problems. The group suggested that nonalcoholic beer kegs, draft-system tubing and beer-pouring faucets should be sanitized regularly to eliminate potential foodborne pathogens and spoilage organisms.

“Without alcohol in beer, you’re removing a lot of the safety net against foodborne pathogens,” Worobo said. “Without that protection that alcohol provides, manufacturers must take into consideration how pathogens may be incorporated from raw products during the processing.”

Said Charles Vegdahl: “If you’re a small craft beer producer creating nonalcoholic or low-alcohol beers – that is, if you’re not making a conventional beer – my advice would be to get your procedures reviewed by an expert process authority.”

In addition to Worobo, Charles Vegdahl and Çobo, Kaylyn Kirkpatrick, of the Brewer’s Association, Boulder, Colorado, who was formerly with Cornell AgriTech, co-authored the work.

The U.S. Department of Agriculture and Cornell funded this research.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe