State supports food processing tech with $600,000 in funding

By Amanda Garris

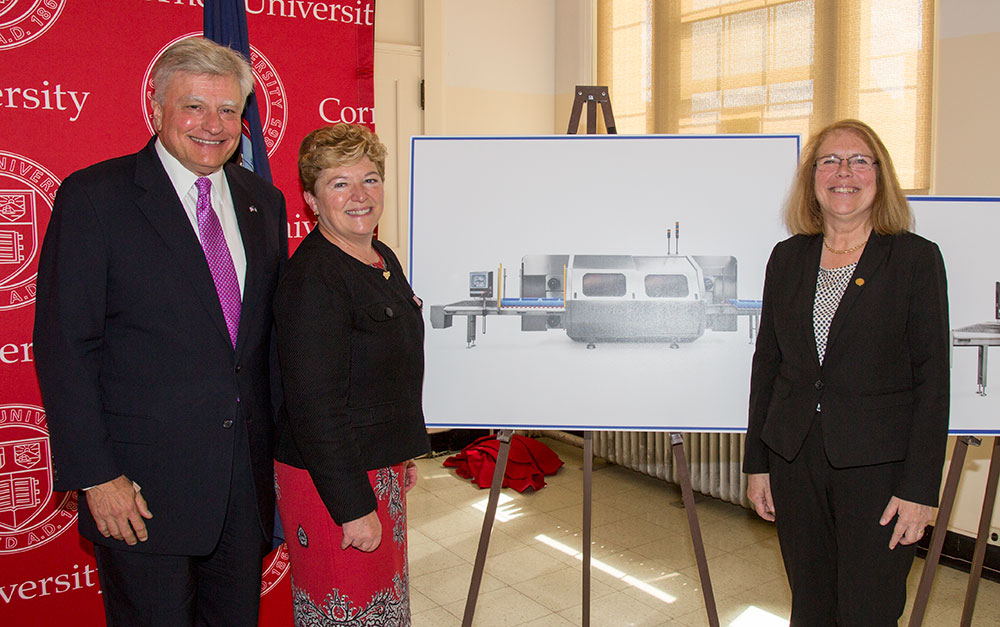

At a Sept. 14 press conference, New York State Sen. Michael Nozzolio, R-54th Dist., announced $600,000 in state funds to bring a new food processing technology to Cornell’s New York State Agricultural Experiment Station (NYSAES) in Geneva, New York. The Hiperbaric 55, which captures fresh taste and extends shelf life while ensuring food safety, will make Geneva a critical part of the validation of this cutting-edge system.

“Bringing this complex high-pressure processing equipment to the New York State Agricultural Experiment Station and to Cornell University is an extraordinary opportunity to promote innovation in Geneva and job growth for New York food processors, especially in the Finger Lakes region,” Nozzolio said.

Traditional food processing relies on high temperatures to kill foodborne pathogens, like Listeria, E. coli and Salmonella. According to professor of food science Randy Worobo, extreme heat is particularly hard on fresh products: It can alter the texture, taste and reduce the nutritional quality. The Hiperbaric 55 uses pressures over 80,000 psi – fivefold greater than the pressure at the bottom of the Mariana Trench – to eliminate pathogens in a quick two- to three-minute treatment. And because the foods are treated inside their final packaging, there’s no risk of contamination of food during packaging.

“Producers like it because there is no quality degradation through heat or cooking, and it retains much of the fresh character and nutrition with a significantly longer shelf life,” Worobo said. “It’s rapidly being adopted across the industry for a range of refrigerated products and ready-to-eat foods, including deli meats, cheese, seafood, dips, salsas and fresh juices.”

The acquisition is a boon for food producers who want to use the new technology, because F.D.A. and U.S.D.A. requirements for food safety mandate the process be tested prior to manufacturing each product. Geneva will become the technology’s validation site for the entire country. Much of the work ahead, according to Worobo, will be to aid companies by establishing “microbial safe harbors,” the safe processing parameters for amount of pressure, length of treatment, the specific food and the type of packaging.

The purchase and installation was made possible by a coalition of public and private funds. In addition to the state funds, private companies who contributed to the purchase include Wegmans, LiDestri, Suja and the unit’s manufacturer, Hiperbaric.

“This exciting partnership represents the best of Cornell University’s land-grant mission, supporting economic vitality for those who grow and sell food products in the state of New York while ensuring the safety of those products for consumers throughout the United States and beyond,” said Kathryn J. Boor, the Ronald P. Lynch Dean of the College of Agriculture and Life Sciences (CALS). “CALS has long been a pioneer in food safety, and the addition of Hiperbaric’s high-pressure processing equipment firmly establishes the college as the leader in this vital field of research.”

For more than a century, NYSAES has been an essential resource for farm, food and beverage industries in New York, from new fruit and vegetable varieties to commercialization of new products. The new equipment is part of a planned modernization of the facilities, for which Nozzolio secured funds last year.

“We sincerely appreciate Sen. Nozzolio’s efforts to secure funding for this important technology that resonates with Cornell’s land-grant mission to advance the common good,” said Cornell University President Elizabeth Garrett. “The addition of high-pressure processing capability to the New York State Agricultural Experiment Station in Geneva will enable Cornell researchers to open new frontiers for food safety while boosting the competitiveness of New York’s food processors.”

Amanda Garris, Ph.D. ’04, is executive editor of periodiCALS magazine.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe