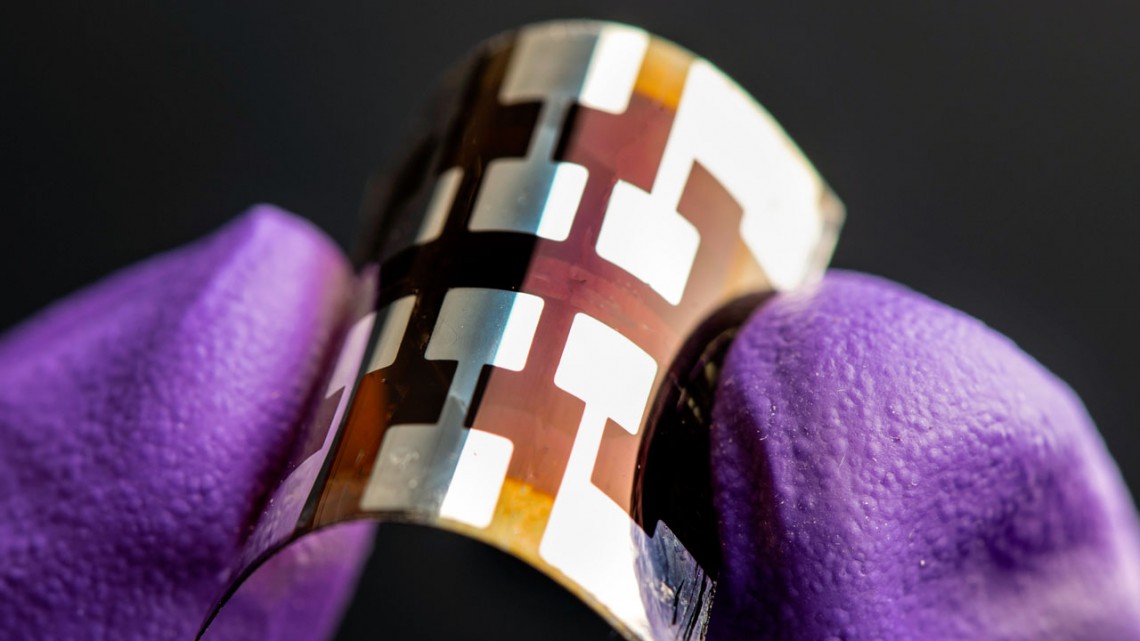

A solar cell made with perovskite, shown here, show promise as an energy-efficient, scalable and longer-lasting way to create solar panels.

Perovskite mineral supports solar-energy sustainability

By Blaine Friedlander

When it comes to the future of solar energy cells, say farewell to silicon, and hello to calcium titanium oxide – the compound mineral better known as perovskite.

Cornell engineers have found that photovoltaic wafers in solar panels with all-perovskite structures outperform photovoltaic cells made from state-of-the-art crystalline silicon, as well as perovskite-silicon tandem (stacked pancake-style cells that absorb light better) cells.

In addition to offering a faster return on the initial energy investment than silicon-based solar panels, all-perovskite solar cells mitigate climate change because they consume less energy in the manufacturing process, according to Cornell research published July 31 in Science Advances.

“Layered tandem cells for solar panels offer more efficiency, so this is a promising route to widespread deployment of photovoltaics,” said Fengqi You, the Roxanne E. and Michael J. Zak Professor in Energy Systems Engineering in the College of Engineering.

“Specifically, perovskites enable affordable and efficient solar panel fabrication,” he said. “Our paper is a thorough energy and environmental assessment of these perovskite-based tandem solar cells, as we try to chart a path for the more sustainable photovoltaics.”

The paper, “Life Cycle Energy Use and Environmental Implications of High-Performance Perovskite Tandem Solar Cells,” compares energy and life-cycle environmental impacts of modern tandem solar cells made of silicon and perovskites.

Producing perovskite-only tandem solar cells leaves a smaller carbon footprint than silicon or perovskite-silicon tandem solar cells. You described making silicon-only cells for solar panels as an energy-intensive process, requiring extreme pressure and heat, and leaving a large of carbon footprint.

Perovskite needs less processing, and much less of the heat or pressure, during the fabrication of solar panels, You said.

Silicon photovoltaics require an expensive initial energy outlay, and the best ones takes about 18 months to get a return on that investment. A solar cell wafer with an all-perovskite tandem configuration, according to the researchers, offers an energy payback on the investment in just four months. “That’s a reduction by a factor of 4.5, and that’s very substantial,” You said.

But solar panels don’t last forever. After decades of service, silicon solar panels become less efficient and must be retired. And as in the manufacturing phase, breaking down silicon panels for recycling is energy intensive. Perovskite cells can be recycled more easily.

“When silicon-based solar panels have reached the end of their efficiency lifecycle, the panels must be replaced,” You said. “For silicon, it’s like replacing the entire automobile at the end of its useful life,” while replacing perovskite solar panels is akin to installing a new battery.

Adopting materials and processing steps to make perovskite solar cell manufacturing scalable is also critical to developing sustainable tandem solar cells, You said.

“Perovskite cells are promising, with a great potential to become cheaper, more energy-efficient, scalable and longer lasting,” You said. “Solar energy’s future needs to be sustainable.”

The first author is Xueyu Tian, Cornell doctoral student in systems engineering; Samuel Stranks at the University of Cambridge is a co-author. The work was partially supported by the National Science Foundation.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe