Best of both worlds: Team proposes novel energy storage model

By Tom Fleischman

A Cornell-led research team has developed a way of combining the large energy-storage capacity of batteries with the superior charge-discharge rate of supercapacitors to come up with a powerful new electrical energy storage (EES) device.

The technology – based on a covalent organic framework (COF) infused with an electronically conducting polymer thin film – could benefit numerous technologies including automotive, by speeding up the charging process, extending single-charge range and even incorporating the device into the body of the car itself.

“Because it is the film that is really providing the charge capacity, it has an infinite form factor,” said Hector Abruña, the Emile M. Chamot Professor of Chemistry. “Any conducting surface can serve as a current collector.”

The group’s work, published Aug. 24 in the American Chemical Society journal Central Science, is the latest installment of a long-running collaboration between Abruña and Will Dichtel, former Cornell assistant professor of chemistry and chemical biology, who’s now at Northwestern University.

Their paper is titled “Superior Charge Storage and Power Density of a Conducting Polymer-Modified Covalent Organic Framework.” Catherine DeBlase Mulzer, Ph.D. ’16, a senior chemist at Dow Chemical, was first author. Other contributors were postdoctoral research fellow James R. McKone and graduate students Luxi Shen and Na Zhang.

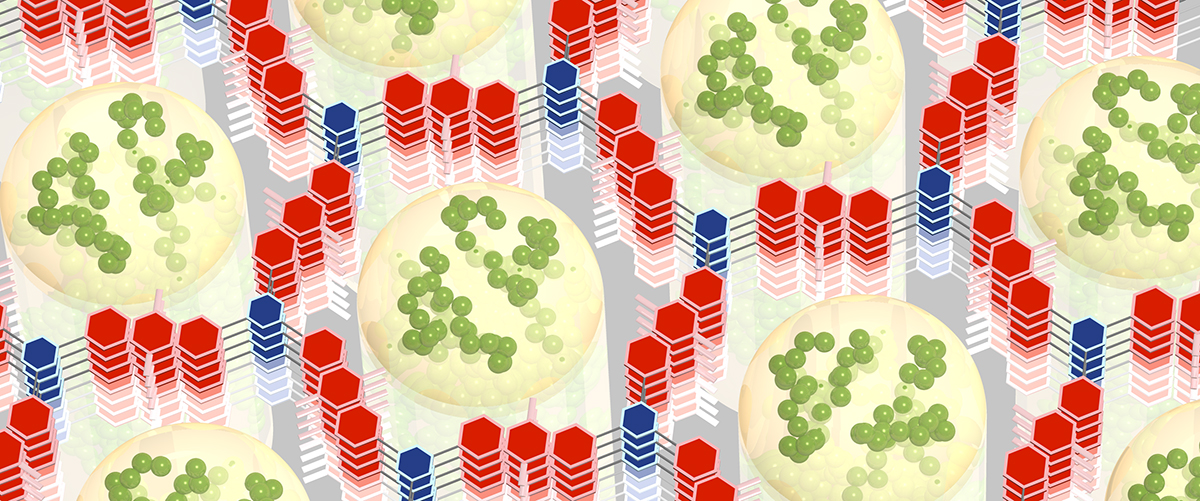

The research, done entirely at Cornell, centers on COFs – porous crystalline structures that can be fashioned into lightweight building blocks with a variety of applications. Conventional COFs were seen as having limited potential for electrical energy storage, however, due to their poor conductivity.

The group developed a way to overcome that limitation: electropolymerizing a thin film of poly (3,4-ethylenedioxythiophene), known as PEDOT (an electronically conducting polymer) – within the pores of the COF, which is grown on a conducting substrate, or base layer.

The resulting enhanced COF film exhibited a 10-fold higher current response compared with unmodified COF films, as well as stable charge-discharge for at least 10,000 cycles.

“The concept is very simple, and the execution was such that it worked,” said Abruña, who in July was awarded the Electrochimica Acta Gold Medal in recognition of his sustained excellence in multidisciplinary studies of electrochemical phenomena. Electrochimica Acta is the official publication of the International Society of Electrochemistry.

The group proved its theory by putting its enhanced, 1-micrometer-thick COF into a coin cell battery prototype and powering a light-emitting diode for 30 seconds.

“It’s one of those rare occasions when you say, ‘Wow, it really worked as designed,’” he said.

Abruña said he’s been in contact with car manufacturers regarding the possibilities of this thin-film EES technology.

“My standard line is, ‘Don’t call it a door – call it a high energy-density module,’” he said. “Because you can coat the inside [of the car door] with this directly on the metal before you paint it, now you have a door that also stores electricity. Yes, this is down the line, but it has a lot of potential.”

Further study will focus on devising even thicker COF films than the 1-micrometer [1,000-nanometer] films used in this study. Previous work with EES devices using two-dimensional COFs featured either multilayer sheets or extremely thin (50-nanometer) films.

This research was supported by a grant from the National Science Foundation, as well as a Department of Energy grant to the Energy Materials Center at Cornell, which Abruña directs. Work was done at the Cornell Center for Materials Research and the Nanobiotechnology Center shared facilities.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe