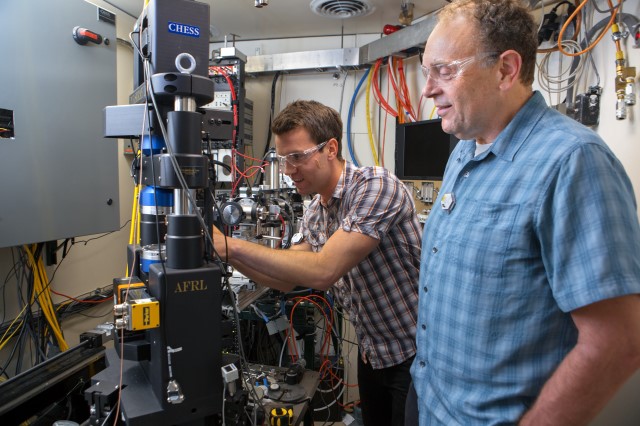

InSitu@CHESS offers material-testing help to industry, academia

By Tom Fleischman

Several years ago, Matt Miller had an idea for using the distinctive X-ray and technical-support capabilities of the Cornell High Energy Synchrotron Source (CHESS) to, in effect, help people build a better mousetrap.

And thanks to a 2014 grant from the Office of Naval Research, InSitµ@CHESS was born.

Miller, professor of mechanical and aerospace engineering, is director of the InSitµ center. Its name is sort of an acronym: It’s the center for “Integrated Simulation and X-ray Interrogation Tools and Training for µmechanics (micro-mechanics) at CHESS.”

InSitµ’s mission is to provide user support for structural-materials analysis using the high-energy X-ray beamline at CHESS, a national user facility supported by grants from the National Science Foundation.

“We’re building a suite of techniques, with the allied tools for analysis, that is attractive to users from national laboratories, government labs and industry,” said Armand Beaudoin, M.S. ’92, Ph.D. ’93, InSitµ’s associate director and industry liaison. He is also professor emeritus of mechanical engineering at the University of Illinois Urbana-Champaign.

“We attract those who are interested in pursuing measurements to support their modeling activity and development of structural materials and applications,” Beaudoin said.

The idea for the InSitµ center was born around 15 years ago, when Miller began going to CHESS to use high-energy X-rays for mechanical testing of materials and examining properties of materials on the single-crystal scale. As the high-intensity light beams shine through a material, the light bounces off the individual crystals.

That diffraction literally sheds light on the material’s structural integrity.

“As I’m putting stress on that sample, the diffraction pattern changes,” Miller said. “And I can see from those changes in diffraction patterns how each individual crystal is being stressed and deforming. This is important because this is the same size scale where cracks initiate.”

X-ray diffraction of the type done at CHESS is nothing new. In fact, 2014 marked the 100-year anniversary of Max van Laue’s winning the Nobel Prize in physics for his discovery of the diffraction of X-rays by crystals.

What is special about CHESS’s X-ray diffraction capabilities, Miller said, is how fast it’s done.

“Using the enormous X-ray flux possible at CHESS and large, high-speed X-ray detectors, we can make thousands of diffraction measurements every second,” he said. “We do van Laue’s simple experiment over and over and over. We get enough views of each crystal so fast that we can literally watch it deform. These X-ray experiments are starting to replace the traditional static, postmortem pictures of microstructure used in traditional materials science.”

The ability to acquire high-fidelity X-ray diffraction data rapidly at CHESS has been enhanced by the ongoing CHESS upgrade, scheduled for completion in 2018, which in part involves replacing or upgrading the X-ray beamlines.

Miller presented his idea for InSitµ@CHESS and request for funding to the naval research office’s William Mullins, Miller’s program officer with naval materials. Mullins was agreeable, Miller said, with one stipulation.

“He said OK, as long as we had industry here from day one,” Miller said. “It was like, ‘I agree with you, I think your tools are fantastic. Now let’s start using them on some real problems.’”

Attracting new industrial users has been a primary goal of InSitµ@CHESS. To assist all of its users, the center forms Industrial Project Teams, composed of faculty, students, postdocs and synchrotron experts from CHESS, and scientists and engineers from industry.

The teams originate from discussions that InSitµ management has with potential industrial partner organizations; the first such partner was heavy equipment maker Caterpillar Inc. Approached by Miller and Beaudoin, the Illinois-based corporation came to CHESS for testing to validate their computer modeling of a welding technique.

“The invitation was particularly good timing for an advanced fatigue analysis project we were already working on at Caterpillar,” said Justin Mach, an engineering specialist at Caterpillar. Mach came to Cornell for the testing.

“Measuring residual stresses in welded fabrications is challenging with a lab-based X-ray source, and even more so when you’re trying to validate predictions from simulations,” Mach said. “CHESS’s invitation gave us an opportunity to collaborate with some of the best in the business and leverage their tools to more efficiently obtain high-quality data to validate our models.”

That collaboration with Caterpillar and Argonne National Laboratory produced a paper published this past March in the Journal of The Minerals, Metals & Materials Society, offering examples of the value CHESS can bring to the table.

The core value of InSitµ@CHESS comes from its hardware and software technology and its people, who provide a bridge between the industry and the synchrotron. With the depths of the science and engineering that are possible at CHESS, industry has an opportunity to address challenges and explore opportunities for future growth.

“We can help industry partners in a variety of ways,” Miller said. “What we need is a commitment that they’ll give us a person we can train on the beamline. With the technology, knowledge and capability in their hands, industry partners will see instantly how invaluable a resource CHESS can be for them.”

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe