First-ever visualization of enhanced catalytic activity reported

By Tom Fleischman

Just as two heads are better than one when trying to solve a problem, two metals are better than one when trying to catalyze a chemical reaction.

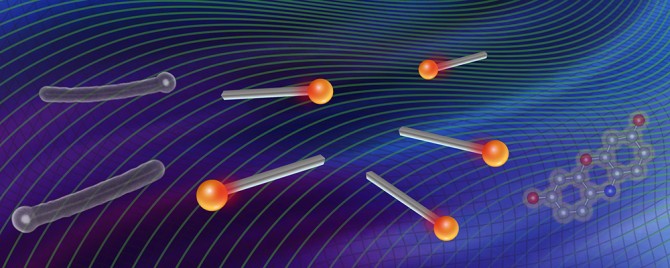

Compared with their monometallic counterparts, bimetallic nanoparticles often show enhanced catalytic activity at the interface of the two component metals. These nanoparticles are important in heterogeneous catalysis, such as when a mix of precious metals in a car’s catalytic converter triggers the reaction of carbon monoxide with oxygen to form carbon dioxide.

Direct measurement of catalytic activity at the bimetallic interface is important for understanding the enhancement mechanism but to date has been hard to quantify.

Peng Chen, the Peter J.W. Debye Professor in the Department of Chemistry and Chemical Biology, has used his expertise in the study of single-molecule catalysis combined with electron microscopy to visualize, for the first time, enhanced bimetallic activity at the metal-metal interface.

His group’s paper, “Bimetallic Effect of Single Nanocatalysts Visualized by Super-Resolution Catalysis Imaging,” was published online Nov. 1 in ACS Central Science, a publication of the American Chemical Society. Guanqun Chen, Ph.D. ’17, formerly of the Chen Group, is the lead author.

For this work, the group used a bimetallic nanoparticle comprising palladium and gold to catalyze a light-induced disproportionation reaction that cleaves a bond between nitrogen and oxygen. This reaction was chosen because it generates a fluorescent molecule, which can be observed by fluorescence microscopy one molecule at a time.

The single bimetallic particle featured regions that were more bimetallic than others, and was just tens of nanometers wide but several hundred nanometers in length. The length gave the researchers the ability to precisely isolate the bimetallic interfacial region.

Using a single particle assured that any differences between the regions would be a function of the metallic interfaces, not the particles. “It’s really important to compare the interfacial region from the non-interfacial region within the same particle,” Chen said, “because there can be a lot of differences from particle to particle.”

Scanning electron microscopy further structurally identifies the bimetallic interface, where the enhancement was further confirmed when breaking that interface through heating eliminated the enhancement. Theoretical calculations provided further confirmation of and insights into the mechanism of the enhanced catalysis.

“This is experimentally observing something that people knew about but couldn’t see, and now we have a new way of directly seeing it,” Chen said.

This super-resolution catalysis imaging can also scan monometallic sites to find areas of higher catalytic activity, which the group says make the best locations for constructing effective bimetallic compounds.

“We found that the more active site of the first metal is also the better site to put the second metal on, so that the bimetallic site is even more effective for bimetallic enhancement,” Chen said.

The group believes that identifying optimal locations of bimetallic sites could guide future development and design of effective bimetallic nanocatalysts. Their work also demonstrates a methodology of using super-resolution catalysis imaging to study bimetallic nanocatalysts, which can be applied to other bimetallic materials.

Other contributors were: Ningmu Zou, Ph.D. ’17, formerly of the Chen group; Bo Chen, a postdoctoral researcher in the group of Nobel laureate Roald Hoffmann, who provided technical advice and facilities for computation; and Eric Choudhary, Ph.D. ’14, formerly of the Chen group and now a senior research scientist at 3M.

Support for this work came from the Army Research Office, the Department of Energy and the National Science Foundation. Part of the work was done at the Cornell Center for Materials Research Shared Facilities and the Cornell NanoScale Science and Technology Center, both supported by the NSF.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe