Graduate student Ronald Heisser builds a model vehicle chassis.

News directly from Cornell's colleges and centers

Powerful design software brings student ideas to life

By Jackie Swift

Ronald Heisser, graduate student in mechanical and aerospace engineering, wants to change the way car chassis are designed. Rather than metal parts welded and screwed together, he reasons, why not echo the way bones, muscles, and tendons work and use organic shapes connected by cables? Instead of the front end crumbling in a collision, a car with this flexible chassis design should spread out the force of the impact and protect its human occupants better.

Heisser came up with the idea for a flexible chassis as part of his Ph.D. work in theoretical and applied mechanics but later decided to set it aside to work on other projects. Then he received an invitation from Autodesk, an international software design company that has partnered with Cornell, to attend an informational meeting about the company’s Fusion 360 software. When Heisser met with Autodesk representatives, they suggested he come up with ways to use the generative design element of the software, and he was back to thinking about that chassis again.

Heisser learned that generative design allows engineers to create dozens of design variations with a few clicks of a button. By defining a project’s size, weight, materials and budget, among other constraints, users supply the software’s artificial intelligence algorithms with a set of specifications to work with. In return, users receive design proposals optimized for their goals.

“My initial idea didn’t even involve generative design,” he says. “But I thought it would play into the concept because generative design is partially about making structures lightweight. So if I can make these organic shapes that I’m connecting with cables more lightweight, the car will have less mass. If you get into an accident, then it’s a lighter structure undergoing impact, so there will be less kinetic energy to transfer to the driver.”

Innovation drives Autodesk-Cornell partnership

Fusion 360 software subscriptions, which include generative design capabilities, are available to Cornell students like Heisser, as well as to faculty, as part of the Autodesk-Cornell partnership first initiated in 2013. At that time, Autodesk donated software to Cornell valued at $51.4 million, among the largest in-kind donations in the university’s history. “Cornell was on a targeted list of schools that we wanted to build a better relationship with,” explains Amy Bunszel ‘89, Autodesk senior vice president, Architecture, Engineering and Construction Design Solutions Group. “A huge number of entrepreneurs have come out of Cornell, and the university’s way of thinking about innovation and entrepreneurship aligned with ours and spoke to us. We were also drawn to Cornell’s emphasis on diversity in the STEM fields and the priority given to interdisciplinary education.”

Bunszel knows first-hand the type of education students receive at the university. A startup founder with a B.S. from Cornell in electrical and computer engineering, she is just one of many Autodesk leaders who are also Cornell alumni. That connection goes back to the early 1990s when Autodesk purchased Ithaca Software, a company based on a 3D graphics system created at Cornell. At that time Ithaca Software founder Carl Bass ‘83, joined Autodesk and went on to hold a number of positions there, including president and chief executive officer. “With so many of our leaders coming from Cornell, we were really excited to be able to support the university’s students and the whole education curriculum with our software,” Bunszel says.

Autodesk products have evolved since that first software gift, and Cornell has continued to benefit from the partnership. Students in mechanical, manufacturing, chemical, civil and biomedical engineering use Autodesk software for a broad range of courses and projects, as do students in the College of Art, Architecture and Planning, and those studying business and entrepreneurship. Faculty also teach using Autodesk tools in a variety of undergraduate and graduate classes.

Mars Rover modified

These days, Autodesk is emphasizing Fusion 360, a single platform that unifies design, engineering, electronics and manufacturing. As part of their outreach to the Cornell community, company representatives regularly visit labs and extend invitations to students to take part in informational meetings like the one Heisser attended.

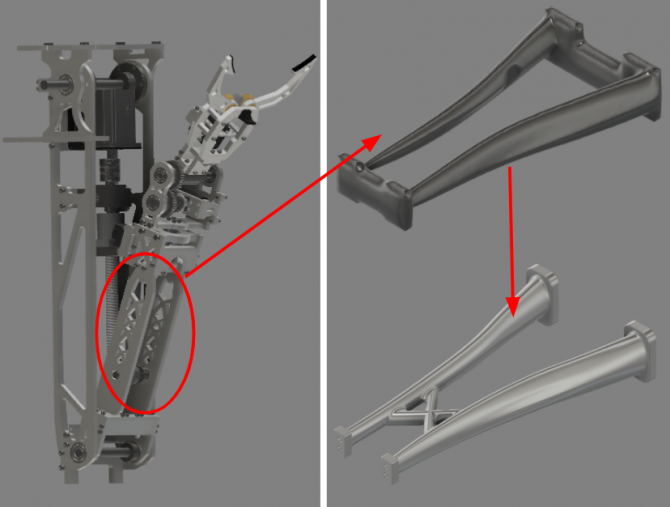

That was how Chris Draikiwicz ‘21, mechanical and aerospace engineering senior and member of the suspension team for Cornell Mars Rover, first heard about the benefits of generative design. Since 2010, the Cornell Mars Rover program has offered students the chance to design and build a fully-autonomous rover to send to the annual University Rover Challenge competition hosted by the Mars Society. Draikiwicz and fellow team members Stephanie Terhaar ‘22 and Mikayla Lahr ‘23 were responsible for designing the suspension for the 2019-20 rover, named Argos.

“We started the design cycle by analyzing the previous year’s system, and we identified it as being very heavy and over spec,” Draikiwicz remembers. “So our driving goal behind the suspension design for Argos was to lighten it. There’s a lot of ways you could do that, but we ultimately chose to manufacture generative design linkages.”

Draikiwicz and the other suspension team members—along with Vicky Hsu ‘21, a member of the drivetrain sub team—spent time getting up to speed on generative design before applying it to the rover. “To use generative design right, you have to get all your loading conditions correct, so we actually conducted some rough accelerometer experiments to get ballpark numbers,” Draikiwicz says.

Once the team had the loading conditions, they input them into the program. “Fusion 360 gave us a design for the main suspension arm,” Draikiwicz continues. “It took us a while to tailor it to something we could machine in-house, but our end deliverable was actually two designs. One was a simplified 2D geometry version, which we made in November of 2019. But we also had an organic-shaped, 3D suspension linkage that we had ready to go for machining in March.”

Unfortunately, the temporary lock-down of the Ithaca Cornell campus caused by the COVID-19 pandemic meant that the students weren’t able to make the organic version. They did utilize the first 2D version however. “We were able to save .8 kilograms across our 50-kilogram rover, which is pretty significant in terms of mass savings,” Draikiwicz says. “The 3D design that I didn’t get a chance to machine would have shaved a further .2 kilograms. If you’re looking at our big goal of cutting mass, all those one-tenths of a kilogram matter.”

A robot’s reach

Reducing mass was also one of the main concerns of Cornell Cup team members who decided to use Fusion 360 generative design capabilities to lighten the arms of their robot known as C1C0 (pronounced Kee-ko). As the hosts of Cornell Cup, a nationwide, embedded systems competition, the Cornell team doesn’t compete, but they do engage in an overall education and awareness campaign aimed at children and teens, and C1C0 serves as their ambassador.

“We’ve heard from a lot of engineers on our team and in the College of Engineering in general that the robots they grew up seeing depicted in the media made them think that STEM fields are interesting,” says Natalia Zeller MacLean ‘21, senior in mechanical and aerospace engineering, overall Cornell Cup team leader, and leader of the Cornell Cup mechanical systems division. “We wanted to make a robot which can provide that kind of inspiration, but in real life. C1C0 shows kids that you can make a cool robot that actually works in the real world.”

C1C0 looks like R2D2 from the Star Wars franchise, except it has arms, and is actually autonomous. “Obviously, that R2D2 shape is not meant to have arms,” Zeller MacLean says. “That means it’s really important for us to make sure the weight of the arms when they’re moving around doesn’t tip the whole thing over or cause steering problems.”

Cornell Cup works closely with Autodesk representatives, who often visit the lab. A few years ago Autodesk suggested that the students come up with ways to use generative design on their robots, and Zeller MacLean and her team mates saw the problem with the arm weight as the perfect application for the software. “Generative design is really good at only putting material in the places where it’s needed,” she says. “Optimizing for less material equals a lighter robot arm.”

At the same time, the students wanted to ensure that the lighter arm still maintained its strength. Team member Samuel Lemma ‘20 took the lead in using generative design for the task. “He used the software to inform the most important structural locations where we actually needed to have pieces of material,” Zeller MacLean says. “He took the original design and ran a generative design study on it and ended up with a 3D model of what was important to keep in and what we could take out. Then he was able to project that down to a 2D sketch.”

Design and manufacturing simplified

The side plates for C1C0’s arm are water jet cut, Zeller MacLean explains, which means essentially cutting holes out of a big sheet of metal. Lemma carried out that manufacturing task, as well, by superimposing the generative design 2D projection onto a sheet of metal plate. “It helped him figure out where to make cuts,” Zeller MacLean says. “It’s informed the overall shape of all the structural portions on the stronger of our two robotic arms.”

Heisser echoes that experience. He had a rough idea of what he wanted for his flexible chassis, he says. “I just sketched where I wanted stuff to go,” he explains. “When it came down to actually making the parts, when it came to designing the structure itself, the software just took care of that for me. In so many ways it simplifies the design process.”

Hearing about Cornell students’ real-life experiences with generative design is music to Bunszel’s ears over at Autodesk. “These students are our future customers, and their feedback is really important to us,” she says. “Making sure our products are relevant to the next generation is a priority.”

Jackie Swift is a freelance writer for the College of Engineering. This story originally appeared in the fall 2020 issue of Cornell Engineering Magazine.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe