Nano-sized McGraw Tower features 161 steps, chimes

By Tom Fleischman

Twenty-four years ago, physics professor Harold Craighead and then-doctoral student Dustin Carr, Ph.D. ’00, created the world’s smallest guitar using cutting-edge technology in what was then the Cornell Nanofabrication Facility.

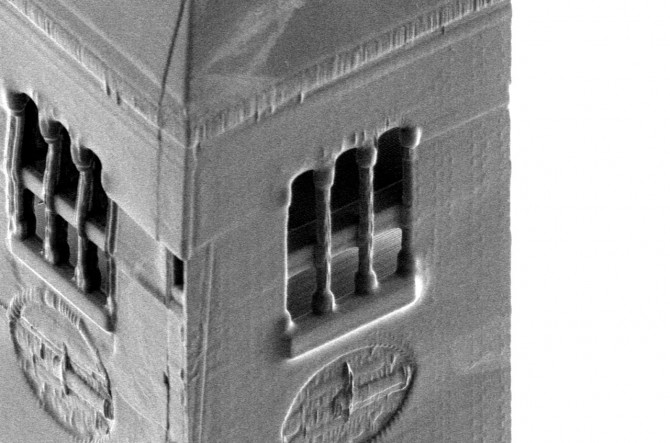

They’re at it again at the center – now known as the Cornell NanoScale Science and Technology Facility (CNF), in Duffield Hall. A team led by staff photolithographer Ed Camacho has created what is thought to be the world’s smallest rendition of Cornell’s iconic McGraw Tower – complete with its 161 interior steps, two sets of stairs and 21 bells.

How small, you ask? It is tiny indeed: Constructed to scale, it is 160 microns wide, 150 microns deep and 1 millimeter tall. A micron is one-millionth of a meter; a millimeter is one-thousandth of a meter. There are just over 25 millimeters to an inch.

Another way to picture it: A penny is approximately 1.5 millimeters thick, so the nano-McGraw would be dwarfed next to the coin.

“This is possibly the world’s smallest bell tower,” said Camacho, whose achievement of epic proportions was accomplished using one of CNF’s newest tools: the NanoScribe GT2 Laser Lithography System, a two-photon polymerization volumetric 3D printer.

One of nine photolithography tools at CNF, the tool – funded by a grant from the National Science Foundation – was acquired in late 2019, and delivered and installed in January 2020. The state-of-the-art NanoScribe GT2 can create 3D nanostructures using a near infrared, femtosecond laser via direct-write onto a photosensitive resin.

The laser sets a focal light cone where a concentration of the light intensity defines the exposure focal spot volume, or “3D pixel.” Using this technique, a 3D CAD (computer-aided design) layout can be broken into an X-Y-Z coordinate system to define the structure pixel by pixel, layer by layer.

Models for printing can be designed using the stand-alone software DeScribe – which comes with the tool – or with any CAD software capable of outputting file formats DXF or STL. And you don’t need to be a photolithography specialist to use the technology.

“This is a commercial device,” said Chris Ober, director of CNF and the Francis Norwood Bard Professor of Materials Engineering in the College of Engineering.

“Fifteen years ago, only a specialist could do this with very specialized equipment,” he said. “Today, with this tool, researchers in the life sciences can make cell scaffolds or microfluidic devices; researchers in photonics can draw 3D waveguides; researchers in robotics can make very small, soft structures for soft robotics – all at this tiny length scale.”

Upon delivery of the NanoScribe GT2, the CNF chose perhaps the most iconic Cornell symbol to demonstrate its advanced capabilities. Camacho said that during the early portion of the pandemic lockdown, he spent a lot of time researching the history behind McGraw Tower.

“I did not find a detailed 3D CAD model of the structure, so I created my own,” he said. “Pictures from the Cornell [library] online archive and the building’s website were used as a reference. My main specifications and assumptions: 173 feet (53 meters) tall, 161 steps, 21 bells, identical sides, two different staircases, two floors at the top, a pyramidoid roof and a Romanesque Revival architecture style.”

The level of detail Camacho was able to achieve is striking: It includes a complete reconstruction of the tower, from the individual external bricks to the dual internal stairways and bells.

“The reason we purchased this tool was because it solves many of the limitations in speed and capacity of the current generation of 2-photon 3D nano-printers,” Camacho said. “Cornell’s McGraw Clock Tower is unique and has the right combination of complexity to display 3D printing at the nanoscale for this flagship tool.”

No, there’s no pumpkin adorning the spire of this tower, but it’s still a monumental achievement.

“Ed’s creation is a tour de force effort, with sentimental value for any Cornellian,” Ober said. “It’s something we can share with K-12 students, proving the reality of nanoscience, and at the same time it’s a wonderful demonstration of what this tool can do, with the details of the interior of the tower put in place.”

Camacho is pushing the envelope of the NanoScribe GT2, working on an even smaller, higher-resolution print with more of McGraw Tower’s fine detail. The goal: to print a 200-micron-tall clock tower – one-fifth the size of the current nano-tower.

Founded in 1977, CNF is a member of the National Nanotechnology Coordinated Infrastructure (NNCI), a network of user facilities funded by the National Science Foundation. CNF enables scientists and engineers from academia and industry to conduct micro- and nanoscale research with state-of-the-art technology and expertise from its 23-member technical staff.

CNF encourages the public to follow its advancements on Twitter, Instagram, Facebook and LinkedIn.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe