Bees begin constructing honeycombs in multiple locations, which they will eventually bridge together.

Engineers may learn from bees for optimal honeycomb designs

By Krishna Ramanujan

Perfect hexagonal structures inspired by honeycombs in bee nests are widely used to build everything from airplane wings, boats, and cars, to skis, snowboards, packaging and acoustic dampening materials.

Challenges arise when space constraints or repairs require engineers to keep a structure mechanically strong when linking together industrial honeycomb panels that each have cells of different sizes. High performance computers used with 3-D printers may solve this problem in the future, but could bees provide a more efficient and adaptable strategy?

A new study finds they can. It turns out that honey bees are skilled architects who plan ahead and create irregular-shaped cells and a variety of angles to bridge together uniform lattices when limited space constrains them.

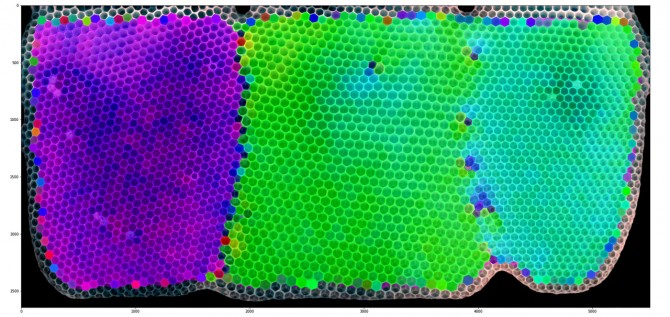

Special imaging of natural honeycombs and computer modeling revealed that worker bees will change the tilt, size and geometric shapes of cells to meet different building challenges, according to the paper, “Imperfect Comb Construction Reveals the Architectural Abilities of Honey Bees,” published July 26 in the Proceedings of the National Academy of Sciences.

“In this fundamental study, we looked at a naturally evolved system which solves similar challenges in a near-optimal manner,” said Kirstin Petersen, assistant professor of electrical and computer engineering in the College of Engineering and a co-author of the paper.

“Understanding how evolution can lead to these organisms that have architectural tricks gives us insights into how you can build structures that are multipurpose, strong, and resilient to different environmental perturbations,” said first author Michael L. Smith, Ph.D. ’17, assistant professor of biological sciences at Auburn University, who began this work while he was at Cornell.

Bees are known to build two types of hexagonal honeycomb cells: small ones for rearing worker bees and larger ones for rearing drones, the male reproductive bees. A challenge – and some forethought – arises when the bees must link lattices made of smaller cells with the larger ones, because the geometries don’t allow for a seamless fit. One issue is that bees don’t remodel their cells. “Whatever action they take in one place effectively decides what’s going to happen later,” Petersen said. Also, for honey bees, wax is the most expensive material energetically, Smith said.

“When they build something out of wax, they’re being as frugal as possible,” said Smith, who is also an affiliate member of the Max Planck Institute of Animal Behavior at the University of Konstanz in Germany.

As a result, the bees employ other shapes – pentagons or heptagons – in order to link together panels of perfectly hexagonal drone and worker cells. Along with building cells of different shapes, the bees also build irregular-sized cells, and sometimes even combine multiple types of irregular cells. The authors refer to these pairs and triplets of irregular cells as “motifs” and show that particular combinations occur more often than expected by chance.

Sometimes the bees will switch from building one type of cell to the other, but they make that change gradually, over multiple cells, which suggests they are thinking ahead, Petersen said.

In the study, Smith set up 12 colonies in the field with frames that lacked the usual wax and wire inside, so the bees could build natural honeycombs without guides. At the end of the season, the researchers took specially lit images and then wrote a custom software to automatically identify, sort and measure the vertices, angles, sizes and geometries of thousands of cells. Coauthor Nils Napp, assistant professor of electrical and computer engineering in the College of Engineering, developed a theoretical computer model that allowed them to analyze configurations, and test optimal ways cells might fit together in a continuous manner under the space constraints. They used the model to ask, how much better could the bees do? “And it turns out, not that much better,” Petersen said.

More than 200 years ago, Swiss entomologist Francoise Huber suggested that bees might use intermediate cells to merge a honeycomb together, but he lacked the modern tools to measure thousands of cells and validate his idea.

“It really required these tools to rigorously show that,” Smith said. “So it’s not surprising that no one has done this before.”

In future work, the researchers may explore if honeycombs are optimized for mechanical strength and test the breadth of the bee’s architectural repertoire.

The study was funded by the Simons Foundation, the National Science Foundation, the German Research Foundation, a Packard Fellowship for Science and Engineering, and GETTYLABS.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe