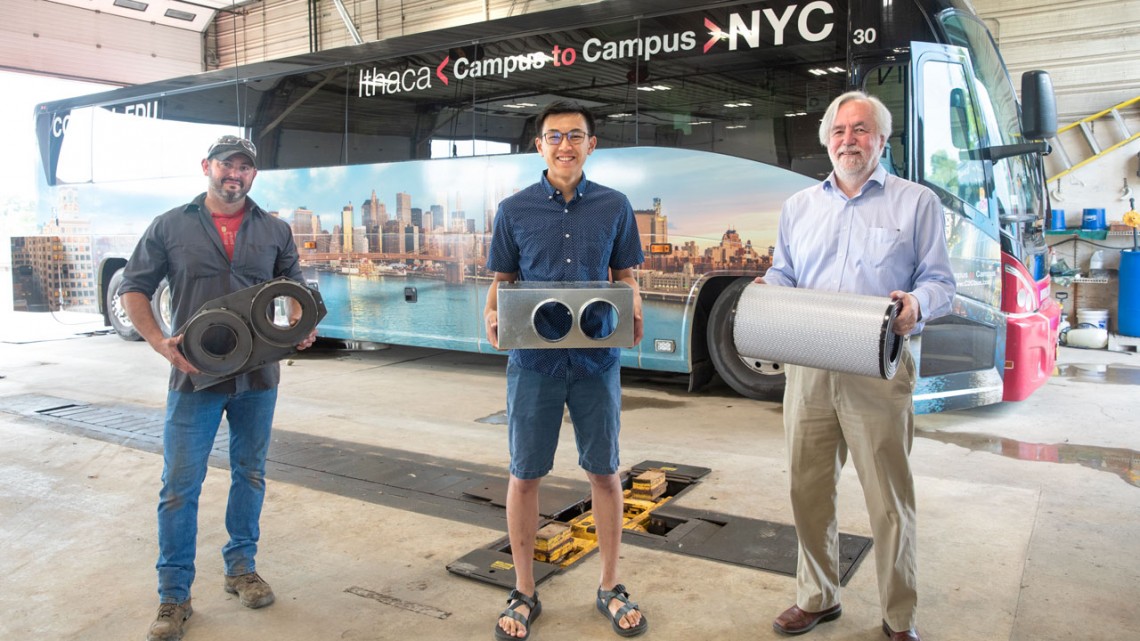

From left, Zach Reed, a mechanic with Transportation and Delivery Services, Christopher Kartawira ’21 and Mark Hurwitz, chief research compliance officer, hold components of the air filtration system that has enabled the C2C buses to resume service.

Grad student is breath of fresh air for C2C filtration project

By David Nutt

The Cornell Campus-to-Campus (C2C) buses have resumed service thanks to a new air filtration system that was designed, built and installed by a team of faculty and staff, and at the center of the collaboration, a master’s student who decided to do something challenging with his summer break.

“It seemed like an interesting problem,” said Christopher Kartawira ’21, a student in the Master of Engineering Program in the Sibley School of Mechanical and Aerospace Engineering. “And it became very hands-on, which gave me insight into how, in the real world, it might be nice to really get the nitty-gritty details of what the airflow looks like, what the viral concentration in the bus looks like. But at the end of the day, they needed something done, and they needed something that works.”

C2C service was suspended March 25, 2020 due to the pandemic. While facilities improvements and safety protocols helped campus operations resume relatively quickly, the buses – which connect Cornell’s campuses in Ithaca and New York City – remained garaged.

“Safety is always our highest priority,” said Bridgette Brady, senior director of Transportation and Delivery Services. “It became evident early in the process of modeling a restart, effective bus air filtration solutions to address our new public health challenges were lacking.”

After more than a year, the need to get the buses back up and running had only increased, but devising a way to reduce potential exposure to COVID-19 in a limited space was still daunting.

“The idea came up that perhaps we had enough knowledge across the campus to figure out how to get the Campus-to-Campus buses running,” said Mark Hurwitz, chief research compliance officer and leader of the Research Division’s multidisciplinary Biomedical Equipment and Testing Rapid Response committee, which was brainstorming ways to address the pandemic’s technological challenges.

“The buses are a critical part of Cornell infrastructure, and it was a missing piece of the economy,” Hurwitz said. “So we settled on making the filtration systems on the buses as efficient for mitigating the virus as those on airplanes.”

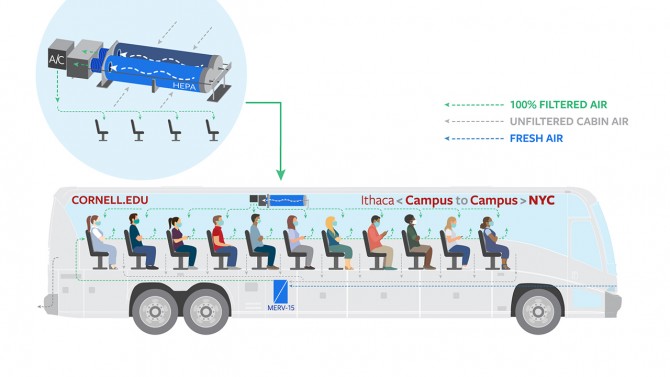

The heating, ventilation and air conditioning (HVAC) systems typically used on buses can filter out large dirt particles, as well as any leaves and rocks that enter the intake valves, but the filters are not fine-grained enough to snare viral particles. Also, the size and layout of buses means there is only so much room available for filtering equipment.

To tackle the engineering challenge, Hurwitz’s group expanded to include several faculty and staff members with expertise in key areas, such as Peter Frazier, the Eleanor and Howard Morgan Professor of Operations Research and Information Engineering, whose epidemiological modeling team helped Cornell safely reopen and navigate the pandemic; Al George, the John F. Carr Professor of Mechanical Engineering Emeritus; Bill Leonard, department of transportation specialist with Cornell Environmental Health and Safety; and Olivier Desjardins, professor of mechanical and aerospace engineering, a world expert in modeling particle motion in turbulent flows.

Frazier’s group calculated the potential transmission of the virus, while Desjardins and his students built a computational system to show how the air flow and viral particles would behave in buses. Hurwitz himself already had deep knowledge of filtration technology, having spent 35 years in research and development at the Pall Corporation, a global supplier of filtration, separation and purification products.

Together, the researchers determined that a system with the appropriate filters in place and proper airflow on the bus could reduce, to no more than 10-15%, the average concentration of what would be emitted by any passenger through their mask, which would still be required to be worn. In addition, each passenger would have a supply of clean air from the nozzle directly above them in the package rack, effectively minimizing any risk of viral transmission.

Once the research team and the transportation department saw that a solution was possible, they set a goal to have the revamped buses running by early August. All they needed now was someone who had the time and skills to put everything together within two months. So they tapped one of the university’s greatest resources: its graduate students.

Kartawira was the perfect candidate because he had specialized in fluid dynamics as an undergraduate and had a very practical approach that can be rare in newly graduated engineers, according to Hurwitz.

“Typically, it takes a couple of years to get a sense of what’s practical and what isn’t. But Chris had that right off. I think that is a tribute to Cornell’s version of engineering education,” Hurwitz said.

“Those of us who were trying to help out had lots of ideas about what the design should be, which could have spun him around in circles for a long time, but instead he narrowed it down to an approach, and he iterated on that very quickly with our comments.”

Most importantly, Kartawira embraced the project’s collaborative spirit, working closely with William Meade, the lead mechanic and fleet manager with Transportation and Delivery Services, and the fabrication shop to custom-build the new components.

‘Overkill, in a good way’

The C2C fleet consists of five buses. The team built prototype filtration systems and tested them on two buses before installing them on the rest.

Each C2C bus already had a pair of HVAC systems: an unfiltered one in the package rack above the seats, which blows out air via window vents, and a main unit underneath the bus that returns filtered air to the system.

The team opted to install upgraded filters on both units. But deciding what type of filter, and where to put them, wasn’t so simple.

HVAC filters are differentiated by the Minimum Efficiency Reporting Value (MERV) rating system. Home HVAC systems, as well as many buses, generally use MERV-8 filters. Systems with MERV-13 filters or higher are most effective at trapping virus particles, according to the U.S. Environmental Protection Agency. The Cornell team set an even more demanding standard: MERV-15, which capture about 85% of particles.

Bus manufacturer MCI planned to offer a new MERV-15 system, but production was delayed. So the Cornell team had to get creative.

They turned to a Rochester company that supplied them with high efficiency particulate air (HEPA) filters. While these filters don’t follow the MERV rating system, they are roughly equivalent to MERV 17-20 and capture upwards of 99.9% of particles. They have a pleated design, which allows for a greater filter area, but that also means they are larger and take up more room. While the HEPA filters fit in the package rack system, they were too bulky for the lower HVAC system.

For the lower system, Hurwitz and Kartawira determined that stacking two layers of MERV-13 filters would reach the MERV-15 threshold.

“In some sense, it’s overkill, in a good way,” Kartawira said. “The filters that we’re using, like MERV-15 media, are meant for hospitals. Buses and transportation vehicles don’t have anything nearly as close.”

Kartawira worked with the fabrication shop to design and install the components and mounting for the new filtration system on the package rack HVAC. Since the buses weren’t built to have such systems in the overhead compartments, Kartawira spent many hours laboring in a hot bus in the middle of the summer to ensure that everything would fit. He and the shop were sent back to the drawing board more than once. And throughout it all, the deadline loomed.

A C2C bus with the prototype system made its maiden voyage on Aug. 6. During post-trip testing, the team found that the duplicate filters on the lower HVAC system were quite dirty and might not be up to snuff.

Then providence intervened, in the form of a delivery truck.

“We were standing around in the garage, saying, well, we’re going to have to figure out how to get something else made,” Hurwitz said. “And in the middle of that conversation, a truck pulled up and the driver said ‘I have a pallet-load of filters for you.’ It was the long-delayed MERV-15 filters from MCI. And those have been running fine ever since.”

The C2C fleet has now resumed service, with buses running Sunday through Friday. The project has been such a success that the Research Division is looking to launch an academic research project that will continue the team’s work in air filtration.

“This project shows what a wonderfully collaborative institution Cornell is,” Hurwitz said. “To have a faculty group that is taking time out of their day, without any real reward for them to participate, but they saw the need; to see the staff jump in and start participating and figuring out how they can help; to have the vice provost of research put money into a project that was not directly going to lead to research dollars, at least not directly; the people in the shops; the people in the transportation unit. Everybody worked together to get this done. I think that speaks volumes about Cornell.”

As for Kartawira, he continues to run diagnostics on the system, taking flow measurements to see if the filters are clogging and making sure the overhead assembly is holding up to vibrations in the road. And, of course, he’s continuing with his regularly scheduled graduate research, in combustion.

“It was kind of nice to have a change of pace and do something different, something that really challenged me,” said Kartawira, who is scheduled to graduate in December. “I’ve been doing a lot more theoretical work, especially during the pandemic. So working on this gave me something to do with my hands, rather than just look at a computer all summer.”

Get Cornell news delivered right to your inbox.

Subscribe