Collaboration is a good fit for wearable sensor startup

By David Nutt

Sometimes you want your technology to be fast, sleek, eye-catching and responsive. And other times? You want to be able to throw it into the wash because it got a little sweaty.

In the case of Organic Robotics Corporation (ORC), you want all of the above.

The Cornell startup specializes in creating soft, stretchable fiber-optic sensors that can be woven into clothing to recognize different types of touch. The wearable technology is proving to be ideal for measuring motion, respiration and fatigue in athletes, with the aim of reducing injuries and improving training and performance.

Now, a collaboration with Cornell’s Performance Apparel Design Lab is taking ORC’s technology to a different field: monitoring the stamina and attention of airplane pilots, astronauts and other highly stressed individuals working in harsh environments.

While these applications seem like natural fits for ORC’s technology, it didn’t start that way.

“Translating a technology from a lab is difficult,” said Rob Shepherd, associate professor in the Sibley School of Mechanical and Aerospace Engineering in the College of Engineering, who co-founded the company with ORC’s CEO Ilayda Samilgil ’19. “Usually a company will listen to problems and then find solutions to those problems. But when you’re doing it from a lab, you have a solution, and you’re trying to find a problem.”

ORC’s proprietary technology, Light Lace, began to take shape about seven years ago in Shepherd’s Organic Robotics Lab. At the time, Shepherd and his team planned to incorporate the stretchable sensors onto soft robots. While that still remains an interest, it didn’t capture the technology’s full potential.

Samilgil suggested applying it to humans instead.

“After conducting customer discovery and talking to potential users, the growing need for human performance tracking and the huge benefit our technology can provide in this market became obvious,” she said.

Samilgil and Shepherd identified a range of possible applications, from pressure monitoring for diabetes patients to high-resolution touch perception and whole-body tracking for augmented and virtual reality simulations. They began fashioning Light Lace into straps that could be attached to any part of the human body. One specific kind of human was an obvious candidate: athletes.

“There’s a particular physiology for each particular sport,” Shepherd said. “Like you would think a tall lanky person is the best kind of pitcher, or a shorter person is the best sprinter. What we want to do is help contribute data that allows everybody to play at the highest level. We want to level the playing field for all body types.”

The softer side of science and design

While other companies have developed products to give athletes a performance boost, Light Lace has a distinct advantage, one that is woven into its very being: it harnesses the power of light, rather than wires and traditional electronics. Each stretchable fiber of Light Lace is about 1 millimeter in diameter. When a laser or LED shines on one end, the light travels the length of the fiber, ending at a component that measures the intensity of the beam and registers any flux caused by bending, stretching or pressure, and pinpoints the location.

The photonic technology consumes less power than its electrical competition, has a higher signal-to-noise ratio, and is washable and recyclable. Unlike other wearable electronics, Light Lace is essentially made with the same types of fibers as the rest of the garment, so its presence won’t distract the athlete. And as an additional perk, because the fibers are glowing with light, they are visually striking.

Those qualities helped the company nab first place in 2021 in both the National Football League’s 1st & Future competition in February and Sun Devil Athletics’ Venture Challenge at Arizona State University in April.

ORC has so far raised approximately $2.5 million in grants and private investment, including a $1 million Phase II award in December 2021 from the National Science Foundation to use Light Lace to measure the bio-motion of baseball pitching.

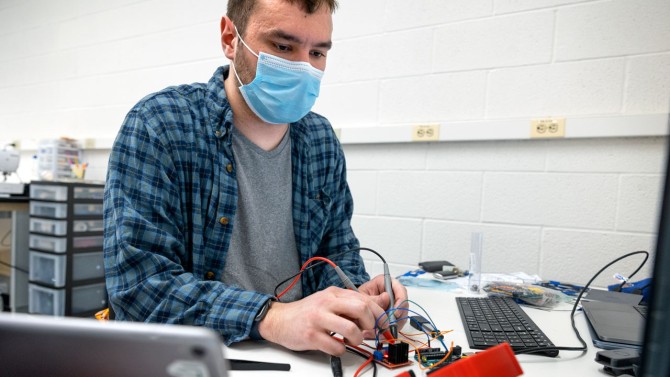

The company has grown in size, as well. Their team now includes two hardware engineers, a biomechanist, a software engineer/data scientist, a fiber science undergraduate and a recently hired data scientist consultant. As a result of the expansion, the company is ready to move into a larger on-campus laboratory in Clark Hall.

To finetune their technology and launch it into the marketplace, the startup has worked with campus partners and supporters such as the Praxis Center for Venture Development and the Center for Technology Licensing and its Ignite – Cornell Research: Lab to Market program.

ORC has also benefited from its interdisciplinary collaboration with Huiju Park, associate professor of apparel design in the College of Human Ecology and director of the Performance Apparel Design Lab.

Park’s research focuses on improving comfort, safety and well-being through creative design solutions, from fire fighters’ protective equipment to military and sports apparel. His lab prototypes, designs and optimizes the wearable system for Light Lace.

“My lab is dealing with the human factors, and how the smart garment interacts with the human body and gets the data we want by incorporating the sensor in the ideal form in the ideal location, using ideal stitches, without being easily damaged or detaching from the body,” Park said. “The human body sweats, and you want to wash the clothing. So we test how durable this garment is going to be. It’s the softer side and user side of science and design.”

The researchers use synthetic materials for their garments – typically nylon and spandex blends – because they are more chemically and physically resilient. These fabrics are also elastic, form-fitting and sensitive enough for the fiber optics to detect subtle body vibrations and movements.

The prototyping process is not unlike a fashion show, except rather than donning haute couture and strutting across a catwalk, the models squeeze into their form-fitting garments and flex and breathe and sweat.

“We see in the situation how the sensor works. Is there anything we need to reconsider in terms of design, form factors, placement?” Park said. “How are we going to incorporate this material to monitor someone’s respiration rate, where we should stitch it, what is the optimal length of a fiber optic, what is the optimal shape on the body? And how we are going to attach or detach sensors? There’s a lot of detail.”

Through trial and error, Park has found some crafty ways to use embroidery to improve the data collection. For example, stitching the sensor in the zigzag pattern of a sine wave, as opposed to a straight line, increases the surface area it covers, ultimately enhancing its sensitivity.

In addition to shirts and straps made with ORC, Park’s group is also applying this approach to sports bras, shoe insoles and military uniforms.

Capturing the data that cameras can’t catch

This month the collaboration received a Phase II award of $750,000 from the Air Force Research Laboratory (AFRL), following a Phase I award last April, to monitor pilots undergoing high-gravitational-force training.

In October, Shepherd and ORC mechanical engineer Tommy Sipple traveled to Wright-Patterson Air Force Base in Dayton, Ohio, for Light Lace’s first in-person pilot test at AFRL’s Human Performance Wing. They strapped sensors onto pilots who were then flung around a centrifuge at speeds up to nine G-forces, and monitored their breathing rate and muscle movements.

“During one of the training tests, we saw a pilot lose vision,” Shepherd said. “Our sensors were able to see that he wasn’t properly tightening his thighs, and that probably contributed to his losing vision.”

The company is also working with the Movement Analysis Lab at Ithaca College, which is using its motion-capture camera system to gather data that will enable ORC to better calibrate their performance-monitoring hardware and software while also serving as a proof of concept for potential partners and investors.

In a typical test, a Cornell student who used to be a baseball pitcher wears the latest prototype shirt and performs specific pitching movements while surrounded by cameras that capture his every move. Afterwards, the researchers collect the data from the cameras and the shirt.

“We do a comparison to see how our systems work better and how we can identify motions and fatigue levels that these cameras can’t,” Samilgil said.

The company has been making progress on how to integrate the fiber optics, Samilgil said, and they are now designing shirts that can track the shape change of biceps and triceps, and shoulder and elbow rotation. Samilgil and Shepherd are hopeful that, with another year of successful trials, they will be ready for production.

“I think we all are most excited about actually testing this with professional athletes,” Samilgil said. “No one in our company would consider themselves an athlete, so that’s the most exciting part: getting some third-party feedback and actually seeing people whose job is literally to wear this.”

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe