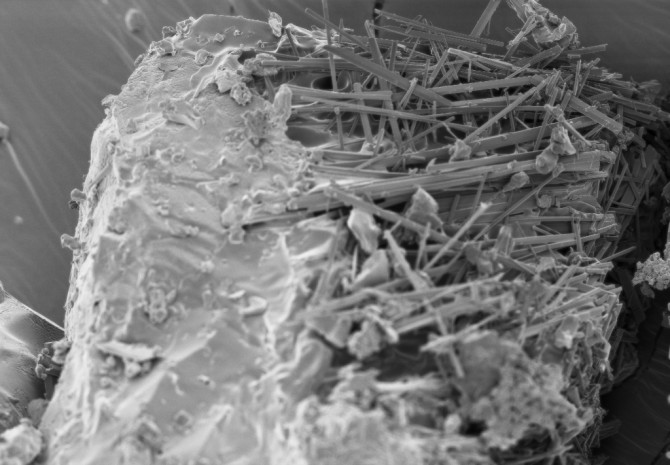

Composite fertilizer-silica pellets prior to dissolution testing.

News directly from Cornell's colleges and centers

Student, NYS business research recycled glass fertilizer

By Syl Kacapyr

There might be a better way to reuse those beer bottles and pickle jars sitting in your recycling bin – use them as fertilizer.

That’s the idea being pursued by Andela Products, an upstate New York business that teamed up with Ryan Greene ’23, M.Eng. ’24, a student in materials science and engineering, to research how waste glass can be turned into an agricultural fertilizer.

Glass, composed of silicon dioxide and often incorporating other elements, can gradually release its components into soil if pulverized into fine particles. Glass fertilizers have gained popularity due to this low solubility, which helps to sustain plant growth while serving as an alternative to fertilizers with harmful chemicals that wash away into the environment.

But the glass particles in these fertilizers are typically made from scratch. The idea proposed by Andela Products is to utilize waste glass by pulverizing it into a fine powder – something the company has perfected with its proprietary equipment used for turning glass into sand and other products – that can be processed into a fertilizer.

“A lot of glass bottles and containers are soda-lime silicates and very high in sodium and calcium,” Greene said. “Our original idea was to exchange those positive ions for nutrient ions – be it potassium, ammonium or something with nutritional value to crops – and do it in an aqueous system at room temperature to cut down on energy cost.”

Greene was introduced to Andela Products through the Department of Materials Science and Engineering’s M.Eng. program, which pairs students with businesses or research labs to investigate real-world challenges. Greene was immediately drawn to the proposal because he had researched plastic bottle recycling as an undergraduate in the College of Human Ecology.

“I was taking soda bottle waste and electrospinning it into nanofibrous facemask filters,” Greene said. “So, the idea of taking away a waste stream, reintegrating it into the economy, and creating a product that could actually be valuable just always resonated with me.”

Using laboratories such as the Cornell Center for Materials Research and the Cornell Mass Spectrometry Facility to analyze results from ion exchange experiments, Greene did not find a significant increase in nutrient concentration through ion exchange. However, the fertilizer salt in the solution was found to precipitate on the surfaces of the silica particles. This behavior not only allowed for a substantial increase in the payload of the resultant material, but also provided a mechanism to bind nutrient-rich silica pellets that can be mixed into soil.

“Those pellets themselves have a dual-phase release,” Greene said. “Some of the salt begins to dissolve and nutrients get taken up by plants, which exposes more salt, and you get this logarithmic curve of it releasing slowly over time. Any subsequent ion exchange of micronutrients from the glass into the soil would simply provide additional benefit.”

Greene added that other findings from the data can be used by Andela Products to explore additional avenues of research.

“I really appreciated the collaboration with the team and Ryan as we developed a testing plan, and then pivoted as needed as the project progressed,” said Cynthia Andela, president and CEO of Andela Products. “Ryan discussed the objectives with the team and then produced the technical data, but also recommended processes that would be important for moving toward commercialization of the final product.”

Greene earned his M.Eng. degree in May and said he intends to stay updated on the company’s product development, adding that he hopes to see outcomes of the research on the market someday.

“That would be really cool to see something I did come to fruition on that kind of scale.”

Syl Kacapyr is associate director of marketing and communications for Cornell Engineering.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe