Medical, fingerprint tech scale up with prototyping awards

By Syl Kacapyr

A polymer that improves drug delivery, an ultrasonic fingerprint reader and a portable blood plasma separator are three promising new technologies being developed into functioning prototypes with help from Cornell Engineering’s Scale Up and Prototyping Awards.

The annual awards, now in their second year, provide teams of engineering faculty and students with up to $40,000 to advance their laboratory research toward functioning prototypes. This year’s awardees discussed what they’ve done with the funding during presentations to the award advisory board March 28.

The prototypes and teams are:

Synthetic polymer for drug delivery: Yadong Wang, professor of biomedical engineering; Xiaochu Ding, postdoctoral associate. Once perfected, Ding said, “We can use this delivery product to treat heart attacks, like myocardial infarctions, and we can also use it for wound healing,” among other applications.

The pharmaceutical industry has sought to improve the delivery of protein-based drugs, which are susceptible to rapid degradation in the human body and can require frequent dosing. A team from The Biofoundry laboratory at Cornell has patented a synthetic polymer that can extend the half-life and enhance the efficiency of protein drugs.

The polymer – poly(ethylene argininylaspartate diglyceride) – is engineered to self-assemble with naturally occurring heparin, among other polymers, to form a multifunctional drug-delivery platform that works like a bodyguard to protect therapeutic proteins. Proteins that bind to heparin are given control over when and where they are released, preserving their biological activity as they travel through the body.

“We’re basically using the biology of the human body to our advantage,” said Wang. “We look at how the proteins are protected in the body and use that same mechanism to increase the half-life of the drug.”

The research team has successfully created a gram of the polymer in their lab, and is using the award funding to develop a method for producing larger quantities. This includes experimenting with different solvents during the manufacturing process because their current method involves the use of toxic solvents that can be expensive and dangerous to discard.

Managing heat transfer during the manufacturing process is also a challenge when attempting to produce larger quantities of the polymer. Wang equates the process to baking a loaf of bread – the larger the loaf, the more difficult it is to evenly bake the bread all the way through.

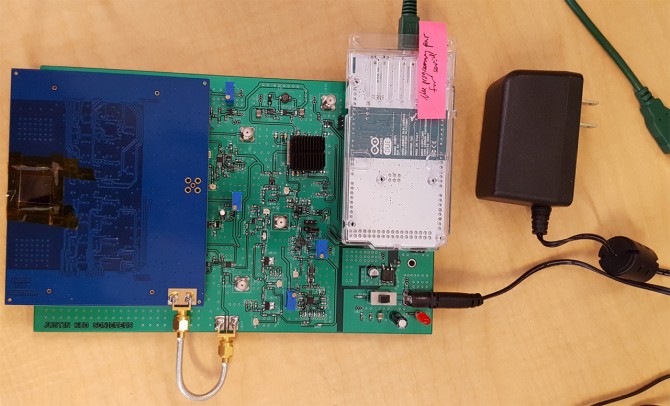

Ultrasonic fingerprint reader: Amit Lal, professor of electrical and computer engineering; Justin Kuo, doctoral student; Mamdouh Abdelmejeed, doctoral student.

Members of the SonicMEMS Lab at Cornell have developed a thin-film gigahertz ultrasonic fingerprint sensor that offers several advantages over fingerprint readers commonly found on cellphones and security systems.

Most modern fingerprint readers use optical or capacitive technology. Optical readers capture the unique ridges and pores of a finger’s surface by shining light on a finger and capturing the reflected light on an image sensor, essentially taking a photograph of a fingerprint to be analyzed. Capacitor readers capture fingerprints by measuring changes in an electric charge caused by the presence of a fingerprint ridge or valley.

The ultrasonic reader created by the SonicMEMS researchers employs an entirely different technology that is more akin to biomedical ultrasound imaging, transmitting an ultrasonic pulse that reflects off of a finger’s surface and back to a sensor. The amplitude of the reflected pulse is used to create an image of the fingerprint.

“One reason you don’t see optical fingerprint sensors on cellphones is because they take up a lot of space. And the reason our technology is better than capacitive sensors is because ultrasound is able to penetrate through glass or metal, which would allow for smartphone manufacturers to increase screen real estate,” said Kuo, who added that ultrasonic sensors are powerful enough to ignore sweat, oil and other finger contaminants that might cause a sensor to not work.

Unlike conventional ultrasonic fingerprint sensors that work at megahertz frequencies and require high voltages, the team’s sensor works at voltage levels compatible with integrated circuits, and at gigahertz frequencies, which potentially allow high-resolution imaging of additional information, such as the stiffness of skin.

The research team is using the award funding to improve the hardware and software of their fingerprint reader from a laboratory scale setup into a portable demonstration unit. Their current prototype is a 64-pixel swipe sensor, meaning the user must swipe a finger across the reader rather than simply touch it. Kuo said one goal is to upgrade the reader into a touch sensor, which is more convenient to use, by increasing the size of the sensor array.

Portable blood plasma separator: Sasank Vemulapati, doctoral student; David Erickson, professor of mechanical and aerospace engineering.

Most diagnostic blood tests require the use of a centrifuge, a relatively bulky and expensive machine that separates plasma from the blood, limiting the ability to perform testing outside a medical or laboratory setting. One of the few alternatives, passive filtration paper, lacks reliability and is limited in its use.

Researchers from Cornell’s Erickson Lab have created a novel, palm-sized blood plasma separator, the High Efficiency Rapid Magnetic Erythrocyte Separator (HERMES). It performs the same high-quality plasma separation produced by a centrifuge, but uses magnetic microbeads that bind to red blood cells, which are then separated from the plasma with the help of a magnetic field.The separated plasma is subsequently transferred to the user so it can be tested on a lateral flow strip.

An early prototype of HERMES used a vortex mixer in conjunction with the magnetic microbeads to separate the plasma, but Vemulapati said an improved prototype uses a technology that simplifies the process.

“We have a solenoid that actuates magnets in a particular direction with respect to the sample, creating a mixing effect,” said Vemulapati, who added that the entire test takes just 1 minute and 50 seconds to complete, and at a cost of less than $2.

The research team is using the award funding to test the prototype outside of a laboratory setting, specifically with people who have little to no medical training. They then plan to manufacture 200 units to deploy at various clinical sites.

Applications for the next round of awards will be accepted beginning Nov. 5; funds will be dispersed in January 2019.

Syl Kacapyr is public relations and content manager for the College of Engineering.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe