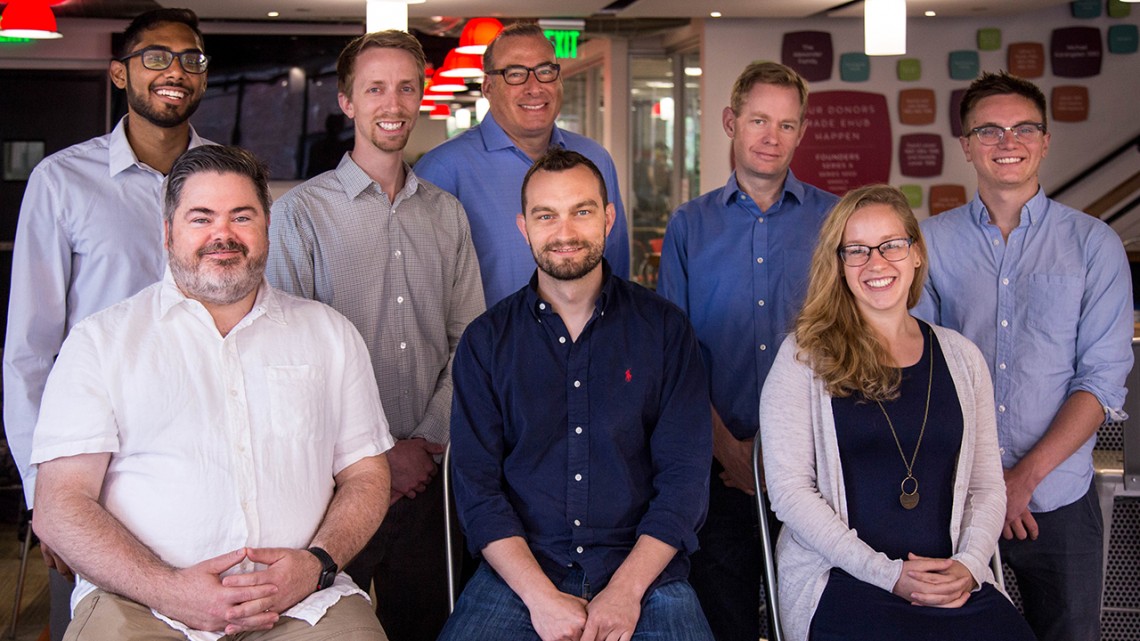

The commercialization fellows and administrators, front row, from left: Tom Schryver ’93, MBA ’02, executive director of the Center for Regional Economic Advancement; Kevin O’Brien, doctoral candidate; and Nicole Diamantides, M.S. ‘17; back row: Sasank Vemulapati, doctoral candidate; Taylor Clawson, doctoral candidate; Steve Gal ’89; David Erickson, associate dean for research and graduate studies in Engineering; and Hunter Adams ‘15.

Commercialization Fellows explore market for inventions

By Syl Kacapyr

New tools for compressing laser pulses, separating blood plasma and 3D printing living tissue are among the technologies students are taking out of the lab and into Cornell Engineering’s Commercialization Fellowship.

Now in its third year, the fellowship offers engineering doctoral students a fully funded summer and semester to explore the market potential for their inventions. The fellows also get to learn and apply new entrepreneurial skills, while receiving more than 500 hours of mentorship from experienced entrepreneurial faculty.

The program hosted its first formal meeting with the 2018 fellows and its academic teaching team on June 12. Students will begin working one-on-one with commercialization experts and Samuel Curtis Johnson Graduate School of Management MBAs to learn about intellectual property, product development and capital fundraising, among other business skills.

The 2018 fellows and their technologies are:

- Hunter Adams ’15: Monarchs – Low-cost, fully autonomous sensor-and-radio chips measuring 5-by-5 centimeters. Each is capable of making local measurements of its environment – including humidity, atmospheric pressure, sunlight and potentially soil chemistry – and communicating that information to other monarchs and data-aggregating receiver stations. The technology can provide farmers with real-time data of crop conditions, helping them to make strategic decisions and monitor pest populations.

- Taylor Clawson: Neuromorphic processing – Algorithms for improved use of autonomous micro aerial vehicles, such as quadcopters used for surveying, search and rescue, and professional videography. The algorithms can quickly and efficiently compute the motion of objects in a vehicle sensor’s camera frame and identify any moving targets in real time using the vehicle’s onboard sensors, requiring minimal computational resources. This can help shrink the size and power requirements of quadcopters while increasing their resiliency to wind and other environmental factors.

- Nicole Diamantides, M.S. ’17: Collagen bioink – A collagen-based bioink that can be used for 3D tissue bioprinting. Most existing bioinks use materials that possess cell-friendly or print-friendly properties, but do not inherently possess both. This bioink naturally displays cell-friendly properties along with improved printing properties of the material, possessing high viscosities and faster gelation times than formulations used with traditional tissue engineering techniques. The bioink can be used for printing tissues such as cartilage, skin and blood vessels.

- Kevin O'Brien: Elastomeric passive transmission– A simple, low-cost device that dynamically modulates the output speed and force of a motor in tendon-driven robotic systems, such as a bionic hand. The transmission is composed of a 3D-printed polyurethane composite and can be used with low-cost motors to achieve the performance of a high-cost motor at a drastically reduced cost. While prosthetics is the initial application for the device, there are numerous other applications for robotics.

- Sasank Vemulapati: H.E.R.M.E.S – The High Efficiency Rapid Magnetic Erythrocyte Separator is a novel method to perform low-cost blood-plasma separation outside of a hospital or laboratory setting. With the help of functionalized magnetic microbeads that capture red blood cells, H.E.R.M.E.S. separates plasma from blood at a fraction of the time and cost of a centrifuge. It does not require any specialized lab equipment and is particularly suited to help decentralize commercial blood testing.

During the fellowship, students develop a plan to commercialize their technology and learn how to think entrepreneurially about research – an invaluable skill, according to the fellows.

“As engineers, we tend to focus a great deal on advancing technology and end up overlooking the needs and wants of the end user,” said Vemulapati, who plans on commercializing his technology after completing his Ph.D.

Adams said he intends to use the fellowship to learn how to incorporate customer feedback into his engineering process, particularly customers in agriculture, where he sees an emerging market for his Monarch sensor-and-radio technology.

Many of the fellows said they applied to the program because they view engineers with business skills as the most efficient vessel for bringing scientific innovation into people’s lives.

Diamantides said her collagen bioink has the potential to benefit many patients, especially because it may gain approval from the U.S. Food and Drug Administration more easily than other bioink formulations.

“Bioprinting is a relatively new field with few bioink products currently commercially available,” said Diamantides. “Having a collagen bioink on the market will allow more researchers and companies to utilize the material to develop products that can get into the clinic to treat patients more rapidly.”

Syl Kacapyr is public relations and content manager for the College of Engineering.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe