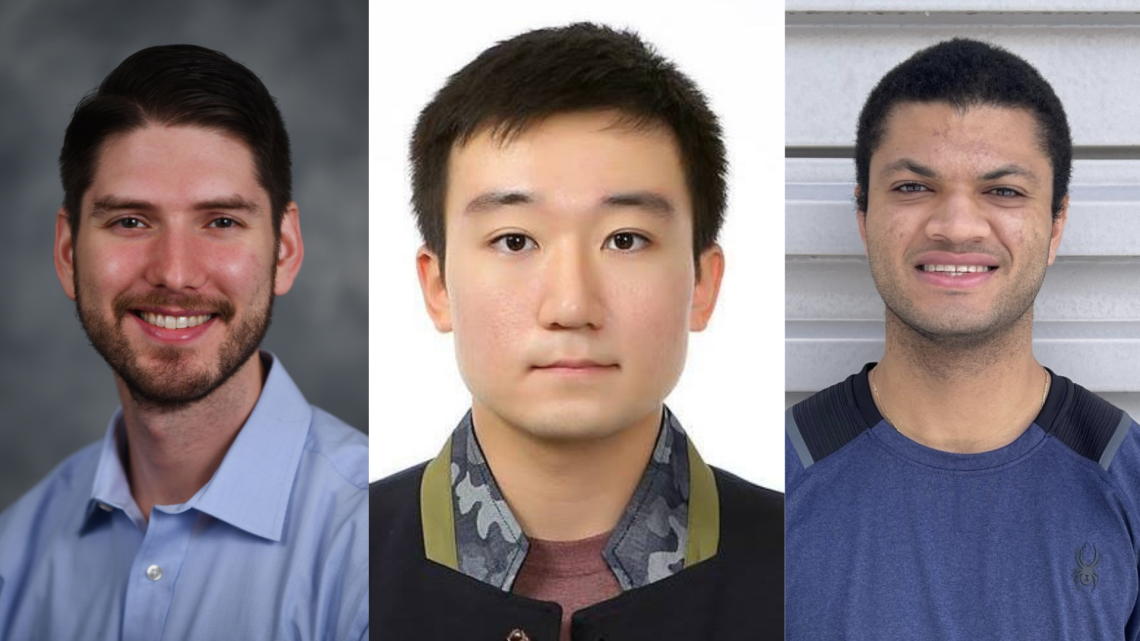

Zachary Manzer, Sean Kim, and Ronald Heisser (left to right) make up the 2021 cohort of Cornell Engineering's Commercialization Fellowship.

News directly from Cornell's colleges and centers

Commercialization Fellows learn to bring research to market

By Grace Collins

Cornell Engineering is pleased to introduce the newest cohort of Ph.D. students selected for the Commercialization Fellowship, a unique opportunity for doctoral engineering students to take a deep dive into the world of entrepreneurship. As the fellows learn the ropes of commercialization, they’re empowered with the skills and mentorship needed to bring their product or technology to market.

Established in 2016, the initiative was created to help researchers overcome the obstacles that can exist when working to execute real-world applications of academic research. During a fully-funded summer and semester, the selected fellows are given access to courses, lectures, Q&A sessions, site visits, and one-on-one mentorship. To round out the experiential learning experience, the fellows also complete an I-Corps Regional Course at Cornell, and participate in NSF I-Corps Teams during the summer.

In collaboration with the Johnson Graduate School of Management, during the second half of the program, fellows are paired with teams of MBA students from Big Red Tech Strategy. The MBA students will assist in finalizing business and go-to-market plans and in developing potential investor pitch materials. This year, in a new addition to the program, the fellows will also be regularly updating an alumni advisory board on their work. The fellowship culminates in December with a pitch presentation to a panel of advisory board members, investors, and alumni.

Meet the 2022 Commercialization Fellows and learn about their technological innovations:

Ronald Heisser, Mechanical and Aerospace Engineering

Micro-Combustion-Powered Tactile Display Arrays

Heisser has developed a soft actuation system, wherein a gaseous methane-oxygen mixture flows through a molded network of fuel micro-channels to supply individual, small-scale, combustion chambers with stored chemical energy. Computer-controlled sparks ignite the gas mixture and cause a silicone membrane covering the chamber to displace outward, serving as a haptic touch stimulation point.

This technology can be applied to develop a computer-controlled refreshable braille display, creating a mass-produced, portable braille device — essentially a “braille kindle” — that visually-impaired individuals can use to interface with computers.

Sean Kim, Mechanical and Aerospace Engineering

Tissue-Engineered Intervertebral Disc with Biodegradable Cage

Intervertebral disc (IVD) degeneration is one of the leading causes of disability, often leading to lower back pain and imposing a significant medical and financial burden on both patients and society. Currently, the surgical options available can lead to complications and further surgeries.

Kim has used tissue engineering (TE) to develop an IVD construct that can restore and regenerate the function of the native tissue, as well as a 3D-printed biodegradable cage. The cage provides the extra mechanical support needed initially, protecting the soft TE IVD constructs until total integration with the host tissue is achieved. This technology will both reduce the risk of revision surgery for patients ,and simplify the time and expense of the procedure for surgeons.

Zachary Manzer, Chemical and Biomolecular Engineering

Cell-free Bioelectronic Membrane Protein Sensors

Manzer’s technology combines cell-free membrane protein synthesis (CFPS) with a supported lipid bilayer (SLB) bioelectronic platform. This innovation allows for a new class of biosensors and bioanalytical devices that use biological proteins as transducing elements, and can read out activity when coupled with an abiotic sensing system. Manzer’s sensing platform represents a new way to isolate and read out activity of transmembrane proteins (TMPs) — a notoriously difficult class of proteins to study, but the catalyst of many biological functions in cells.

Pharmaceutical companies have made a large financial commitment to screen TMPs and use them as a target for disease mitigation. This technology can potentially drastically reduce the screening time and cost for identifying potential disease targets.

Learn more about the Commercialization Fellows program and stay up-to-date with this year’s participants.

Media Contact

Get Cornell news delivered right to your inbox.

Subscribe